Our History

Rogers Corporation was founded by Peter Rogers as Rogers Paper Manufacturing Company in 1832.

For the best experience, expand the e-book to full screen.

Keep Exploring

For more Rogers history, these short videos give a bite-sized look at different moments in time.

-

Celebrating More Than 190 Years of Rogers

Celebrating More Than 190 Years of Rogers -

Rogers, CT: A Company Town

Rogers, CT: A Company Town -

Rogers Commitment to Sustainability

Rogers Commitment to Sustainability -

Employee Contributions and Achievements

Employee Contributions and Achievements -

The Rogers Way to Innovate

The Rogers Way to Innovate -

Rogers Driving the Future

Rogers Driving the Future -

Rogers Global Expansion

Rogers Global Expansion -

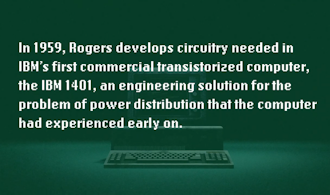

A Technology Milestone

A Technology Milestone -

Rogers in 1997: High Frequency Laminates

Rogers in 1997: High Frequency Laminates -

Rogers in 1987: A Plastic Car Engine

Rogers in 1987: A Plastic Car Engine -

Lurie Research and Development Center

Lurie Research and Development Center -

Rogers Corporation History Book

Rogers Corporation History Book -

Rogers Materials in Space Exploration

Rogers Materials in Space Exploration -

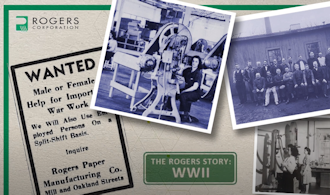

Rogers' Role in WWII

Rogers' Role in WWII -

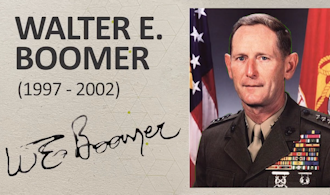

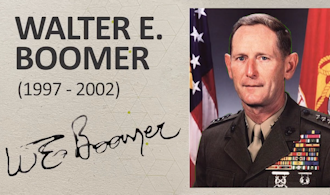

Rogers Leaders: Walter E. Boomer

Rogers Leaders: Walter E. Boomer -

We Are Rogers

We Are Rogers -

Rogers Corporation Origins

Rogers Corporation Origins -

Timeline of Technology Advancements

Timeline of Technology Advancements -

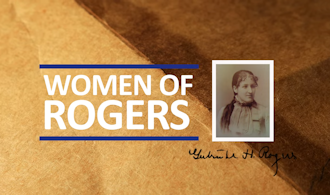

Women of Rogers: Gertrude Rogers

Women of Rogers: Gertrude Rogers

-

Celebrating More Than 190 Years of Rogers

Celebrating More Than 190 Years of Rogers -

Rogers, CT: A Company Town

Rogers, CT: A Company Town -

Rogers Commitment to Sustainability

Rogers Commitment to Sustainability -

Employee Contributions and Achievements

Employee Contributions and Achievements -

The Rogers Way to Innovate

The Rogers Way to Innovate -

Rogers Driving the Future

Rogers Driving the Future -

Rogers Global Expansion

Rogers Global Expansion -

A Technology Milestone

A Technology Milestone -

Rogers in 1997: High Frequency Laminates

Rogers in 1997: High Frequency Laminates -

Rogers in 1987: A Plastic Car Engine

Rogers in 1987: A Plastic Car Engine -

Lurie Research and Development Center

Lurie Research and Development Center -

Rogers Corporation History Book

Rogers Corporation History Book -

Rogers Materials in Space Exploration

Rogers Materials in Space Exploration -

Rogers' Role in WWII

Rogers' Role in WWII -

Rogers Leaders: Walter E. Boomer

Rogers Leaders: Walter E. Boomer -

We Are Rogers

We Are Rogers -

Rogers Corporation Origins

Rogers Corporation Origins -

Timeline of Technology Advancements

Timeline of Technology Advancements -

Women of Rogers: Gertrude Rogers

Women of Rogers: Gertrude Rogers

The Impact of Innovation: The Rogers Story

Learn more about our history and what’s ahead.

Download PDF