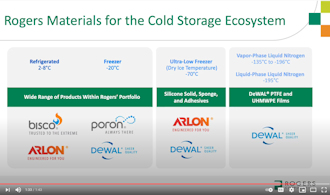

Rogers offers a broad range of materials that preserve and protect sensitive products at a multitude of temperature levels throughout the cold storage supply chain.

Our materials perform exceptionally well at standard equipment temperatures, from refrigerated (2° C to 8°C), to freezer (-10°C to -25°C), to ultra-low freezer (-70°C to -90°C), to liquid- or vapor-phase nitrogen (-135°C to -196°C) with no compromise of mechanical properties.

A typical silicone elastomer material reaches low temperature embrittlement around -55°C. Several ARLON silicone materials, however, function at temperatures well below this. An ARLON GP grade solid silicone material, for example, can reach temperatures as low as -62°C. An ARLON HS/LT grade solid silicone offers even lower temperature usage, reaching a low temperature of embrittlement around -90°C.

Our BISCO® silicone foam and PORON® polyurethane materials are available in a wide range of firmness and thickness options and display superior compression set (C-set) retention, ensuring a robust and consistent enclosure.

For applications requiring high-performance films and/or pressure-sensitive tapes, DeWAL® products provide reliable and thermally stable solutions.

In addition, DeWAL PTFE (Polytetrafluoroethylene) is an ideal material for critical medical, biological and pharmaceutical applications, as it has a natural resistance to most chemistries, is biologically inert and offers an excellent range of operational temperatures, from -200°C to 260°C.