Published

by Rogers Corporation

Elastomeric Material Solutions

Recent developments in eMobility (electro mobility or advanced mobility) have led to increasing options for clean and efficient vehicles that rely on electric powertrain technologies, in-vehicle information, communication technologies, and connected infrastructures. The systems within these vehicles pose unique sealing and vibration management challenges vs cars with traditional combustion engines.

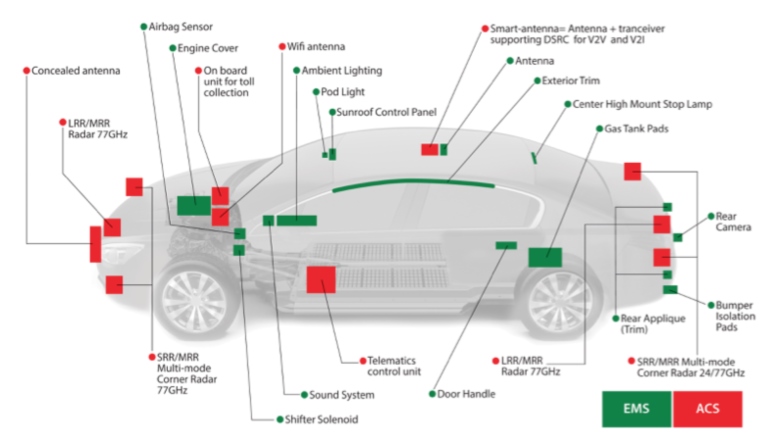

Rogers’ advanced materials are used in a wide variety of eMobility platforms, including gaskets and vibration management foams for airbag sensors, sound systems, and batteries. Let’s take a closer look at the challenges of vibration management and gasketing / sealing in EVs and hybrid vehicles.

Learn how Rogers advanced materials are used in a wide variety of eMobility platforms.

High performance gaskets are found in Exterior Lighting Seals; On-board EV Charging Seals; Roof Mounted Antenna Seals; Sensors; Back Up Camera Seals; Drive Train PCB Isolation Pads; EV & HEV Battery Isolation/Battery Separator & Compression Pads; Heat Shields; Buzz, Squeak and Rattle Isolation (BSR) Pads; Noise, Vibration & Harshness Isolation Pads; and Tolerance and Gap Pads.

Vibration management foams are found in Dampers/Isolators for Shock, Vibration, Noise & Impact; Gas Tank Isolator Pads; Airbag Sensor Arm Rest Pads; Door Handle Isolation Pads; Infotainment Display Seals; Isolation Pad Interior Trim for Cup Holders and Bin Liners; and Sunroof Control Panels.

High Performance Materials

Rogers’ Elastomeric Material Solutions group provides a wide range of high performance materials, from soft foams for automotive fuel tank isolator pads and camera window gaskets to very firm foams for enclosure gaskets. The company’s foams – PORON® polyurethane material and BISCO® silicone materials– provide solutions for door panels, air bags, instrument panels, battery systems, and more.

Vibration Management

Automotive interiors and exteriors are subjected to a variety of extreme environmental conditions. Safety is also a concern as severe damage – electrical shock or explosion – is possible if the vehicle’s battery pack is not properly sealed. Batteries need to be packaged to absorb internal impact energy. Vibration must be managed both within the pack and between the pack and the surrounding vehicle.

- BISCO® Silicone Compression Set Resistance (C-set) withstands collapse due to the stresses of compression and temperature over time. This extends the life of the vehicle part by continuing to seal and absorb shock.

- In EV / HEV batteries, cushions/springs hold components firmly in place and, if needed, firmly in contact with each other. PORON® polyurethane materials have a unique ability to produce a very consistent level of force across a range of compressions. This allows the system designer to predict the material’s behavior across varied dimensional tolerances.

Gasketing, Sealing, and Gap Filling

Like most vehicles, EVs and HEVs need to withstand the elements and function in all environments. Gaskets and gap fillers protect sensitive electronics – often in the presence of extreme temperatures – and seal out air, water, dust, light, and electromagnetic interference (EMI).

- Gaskets made from BISCO® silicone materials seal the interface, such as where a battery is plugged into the electrical grid, and provide exceptional UV resistance and cold temperature flexibility.

- PORON® polyurethane materials are low-outgassing and non-fogging. They contain no plasticizers or residual chemicals to contaminate devices. Wherever it is used, the material will not become brittle and crumble, and is non-corrosive to metal.

Tags:

Automotive & EV/HEV

Published on May 31, 2017