Published

by Rogers Corporation

Elastomeric Material Solutions

Are you considering silicone and want to know how it compares to other commonly used elastomers? Maybe you’re just wondering if there are any good alternatives to silicone? You’ve landed in the right place.

With so many different elastomeric material design options out there, the ability to quickly compare can help you make a well-informed decision. After all, choosing the right material can greatly impact the performance and longevity of your application.

We’re here with our Principal Technical Service Engineer, Dan Kubick, to walk through some common silicone material comparisons and see if there are any real alternatives to silicone to consider.

We will cover how silicone compares to the following elastomeric materials: polyurethane, EPDM, NBR, neoprene, and polyethylene. Let’s get into it.

Want a quick visual summary?

When Comparing Silicone to Other Materials, Where Do I Start?

- Application Needs

Start by reviewing your application needs. Here are a few basic questions you should ask about your application requirements:

- Does the material need to perform in low and high temperatures?

- Does the material require chemical resistance to a particular fluid?

- Is the amount of compression set resistance (or memory) of the material important?

- Does the material need to withstand long-term ozone and/or UV exposure?

- Can you settle for a material that is “good enough” or is the application mission-critical?

- Material Properties

Beyond application requirements, you should also consider material properties. When comparing silicones to other materials, you should consider factors such as:

- Mechanical flexibility and/or conformability

- Durability

- Temperature resistance

- Chemical resistance

- Balance Your Priorities

Overall, comparing material options is usually about finding the right balance between performance, budget, wants, needs, and risks. Most importantly, when comparing material options, ask yourself:

- What is most important in my application?

- Do I have any non-negotiables?

- What is my budget?

- What are my risks?

Read our detailed guide on the top material design considerations you need to consider.

Are There Any Real Alternatives to Silicone?

Well-renowned for its versatility and long-term performance, it’s no surprise that silicone is a popular material design choice. But is it the best choice of all the other elastomeric material options?

Let’s explore how silicone compares with other materials such as polyurethane, EDPM, NBR, neoprene, and polyethylene.

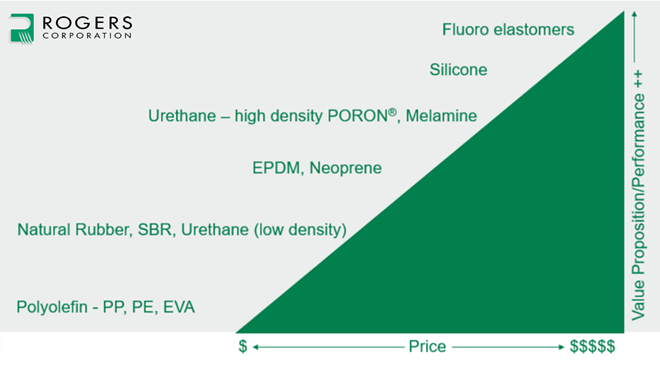

Price vs. Performance Comparison

While the price may seem comparatively high, the properties of silicone make it one of the best choices when designing key components that require consistent performance over a wide range of temperatures.

The graphic above illustrates that silicone foam is a high-performing material across most of the commonly used materials in the industry. In general, as material performance increases, price increases as well.

Properties Comparison

Let’s explore the material properties of silicone a bit further.

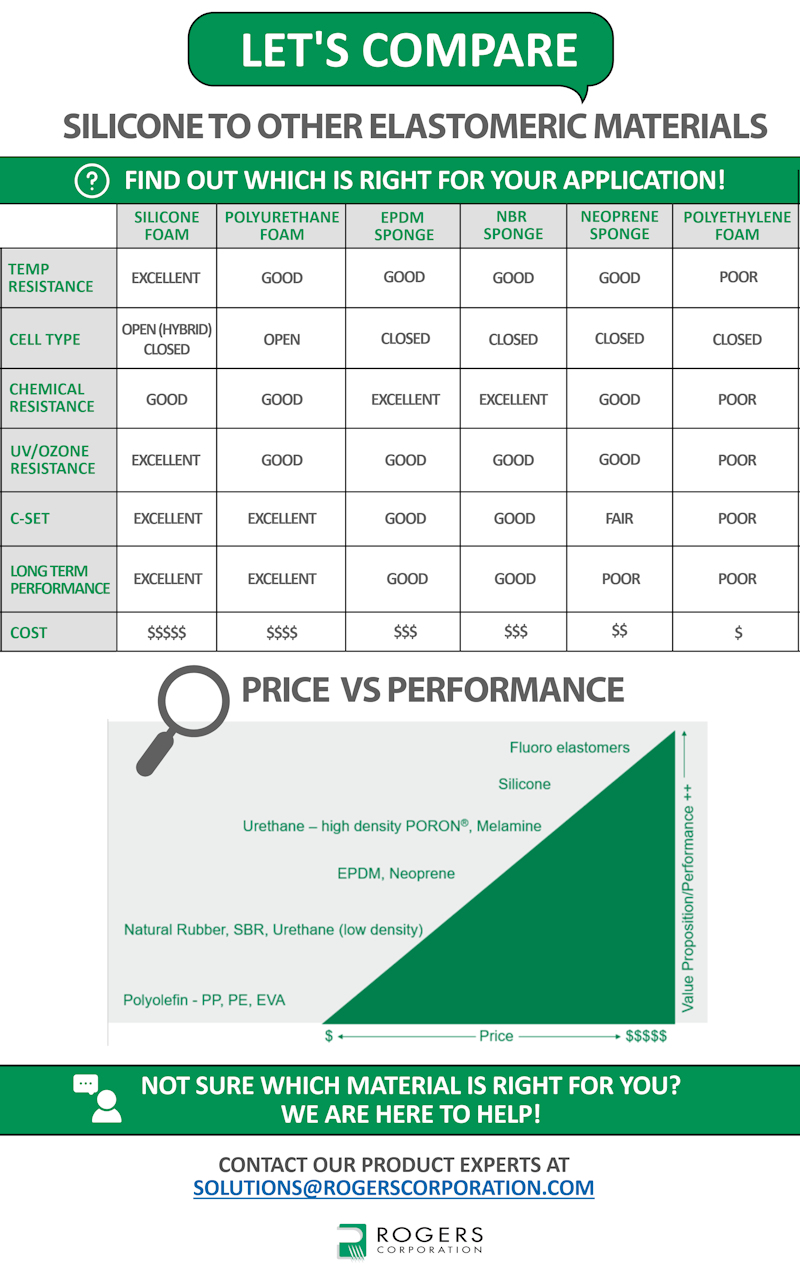

A general property overview comparing silicone to polyurethanes, EDPM, NBR, neoprene, and polyethylene is shown in the table below.

| Silicone Foam | Polyurethane Foam (Ether) | EDPM Sponge | NBR Sponge | Neoprene Sponge | Polyethylene Foam | |

|---|---|---|---|---|---|---|

| Temperature Resistance | Excellent | Good | Good | Good | Good | Poor |

| Cell type | Close/Open (Hybrid) | Open | Closed | Closed | Closed | Closed |

| Chemical Resistance | Good | Good | Excellent | Excellent | Good | Poor |

| UV/Ozone Resistance | Excellent | Good | Good | Good | Good | Poor |

| Compression Set | Excellent | Excellent | Good | Good | Fair | Poor |

| Long Term Performance | Excellent | Excellent | Good | Good | Poor | Poor |

| Cost | $$$$$ | $$$ | $$$ | $$$ | $$ | $ |

Silicone exhibits the best overall performance properties of commonly-used materials. From temperature resistance to compression set to long term performance, few materials compare to silicone. However, it is also generally the costliest of the material options. But can the high cost translate to savings in the long run? Read an in-depth discussion on whether investing in silicone is the right choice for your application.

Are There Enough Silicone Options To Meet My Application Needs?

Once you have determined that your application would benefit from silicone’s performance and properties, what is the next step?

Rogers Corporation is a global silicone solutions leader, offering a broad portfolio of material forms (cellular and solid) , thicknesses, firmness, and colors. Our BISCO® Silicones, ARLON® Silicones, and Silicone Engineering® high-performance silicones offer a wide breadth and depth of possibilities. To aid in narrowing down the right silicone solution for your needs, read more about Rogers silicone brand offerings and types.

Key Points

Material selection largely relies on your application requirements and whether a material other than silicone can meet those requirements to the desired level.

Silicone, while a more costly option, exhibits the best performance properties compared to other common materials like polyurethane, EDPM, NBR, neoprene, and polyethylene.

The Rogers Technical Service and Development Team are ready to provide technical assistance and design support. Rely on Rogers to help you find the best material for your unique application. Contact a Rogers Sales Engineer to get started. #RelyOnRogers

Related Content

- How to Choose the Right Silicone: Top 6 Considerations

- Beyond the Price Tag: Long-Term Savings with Silicone

- How to Narrow Down Silicone Brands from Rogers Corporation

Published on May 18, 2024