Published

by Rogers Corporation

Elastomeric Material Solutions

ARLON® Water Resistant Substrate Helps Prevent Snow and Ice Buildup in Doorways

When temperatures plummet and snow covers the ground, trains face unique challenges to keep running smoothly. One of the most critical components affected by harsh winter conditions is the train door.

Exposed to moisture, snow, and ice, these doors are at risk of freezing, which can lead to operational disruptions and safety concerns.

So, what’s the secret behind keeping train doors functioning flawlessly even in the coldest weather?

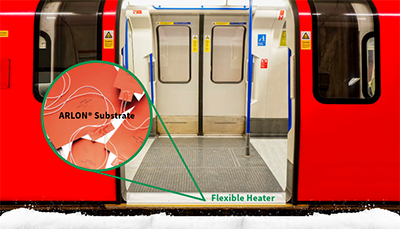

The answer lies in the integration of a flexible heater with a waterproof substrate that conforms to the door’s shape. This design ensures even heat distribution while preventing moisture ingress, effectively stopping snow and ice buildup in the harshest winter conditions.

Material Design Considerations

When designing for extreme winter conditions, engineers must prioritize materials that offer:

- Flexibility – Conforms to the unique shapes of doorways.

- Water and Environmental Resistance – Withstands exposure to moisture and harsh conditions.

- Durability – Provides long-lasting performance in rugged environments.

- UL Certification – Meets critical safety and flammability standards.

- Heat Transfer Efficiency – Ensures effective and consistent warming.

- Thermal Stability – Performs reliably across a wide temperature range.

The Rogers Solution

One train manufacturer decided to use flexible heaters, constructed with ARLON® Silicone Water Resistant Substrate from Rogers Corporation, in the doorways of their trains. The substrate was chosen for its exceptional waterproof properties, which reduces the risk of circuit failure due to moisture ingress.

ARLON Substrate Material Composition and Benefits:

- Silicone and PTFE Construction – The substrate features silicone bonded to a PTFE film, providing an impermeable barrier against water.

- High Heat Transfer and Durability – Delivers efficient thermal conductivity and withstands extreme conditions.

- Wide Temperature Range – Thermally stable from -58 to 232°C (-72 to 450°F), delivering reliable performance in varying climates.

- Dual-Sided Surface – One side cured, the other uncured, allowing for easy bonding to metal surfaces in train doorways.

- UL Certification – Complies with UL 94 HB and V-0 standards, with RTI ratings up to 220°C, meeting stringent transportation safety requirements.

Result

Due to the excellent water-resistant properties of ARLON Silicone Water Resistant Substrate, all the manufacturer’s specifications were met. As a result, their trains operate smoothly and safely for all passengers, even in the harshest weather conditions.

Learn More

- Explore ARLON Silicone Flexible Heater Substrates and request a sample

- Contact a Rogers Sales Engineer

Related Content

- The Engineer's Toolkit: 8 Best Tools for Effective Material Selection

- How to Choose a Reputable Silicone Supplier: Top 6 Tips

- Everything You Need to Know About Compression Set for Elastomeric Foam Materials

Related Products:

Arlon Silicones

Tags:

Rail

Published on Sep 12, 2024