Published

by Rogers Corporation

Elastomeric Material Solutions

In our last blog, we outlined why temperature is a crucial factor in design and material selection. Now we will take a closer look into the ideal temperature ranges for various material types and guide you on where to find temperature information for specific Rogers Corporation materials.

The material types we will discuss include:

- Silicones including offerings from the BISCO® and ARLON® product portfolios

- Polyurethanes, including PORON® cellular materials

- PTFE materials offered by DeWAL®, including film, tape and specialty formats

- UHWM-PE films, tapes and composites from the DeWAL product portfolio

What is the Temperature Range for Silicone?

Polyurethane materials have a versatile range of temperature tolerances depending on their application and specific formulation (for example, whether they are ester or ether-based). Generally, the temperature range for polyurethane materials is:

| Min. | Max. | Short-term Exposure (Max.) | |

|---|---|---|---|

| Foam | -55°C (-67°F) | 200°C (392°F) | 225° C |

| Sponge | -75°C (-103° F) | 232° C (449°F) | 250° C |

| Solid | -75°C (-103° F) | 232° C (449°F) | 250° C |

The minimum and maximum temperature is also known as the continuous temperature range.

A critical feature of silicone is its ability to preserve flexibility in low temperature environments instead of becoming hard and brittle like many other materials. Additionally, heat does not degrade silicone's high-performance properties in high-temperature environments.

These properties make silicone materials suitable for a wide range of applications, including automotive, aerospace, electronics, and medical devices, where both high- and low-temperature performance is required.

What Happens if Silicone is Used Outside of its Designated Temperature Boundaries?

It depends on how far out of the temperature boundary and how long the material is exposed to these conditions. At high temperatures outside of its boundaries, silicone may experience degradation in its mechanical properties, leading to reduced elasticity and even deformation. Silicone may lose flexibility at low temperatures outside of its boundaries and be susceptible to cracking. In general, exposing a material to temperatures outside of the specified temperature range compromises performance and can potentially result in safety and reliability issues as well as reduce the lifespan of the application.

What is the Temperature Range for Polyurethanes?

Polyurethane materials have a versatile range of temperature tolerances depending on their application and specific formulation (for example, whether they are ester or ether-based). Generally, the temperature range for polyurethane materials is:

| Min. | Max. | Short-term Exposure (Max.) | |

|---|---|---|---|

| Low Density Foam | -62°C (-80°F) | 93°C (200°F) | 150° C (302° F) |

| High Density Foam | -62°C (-80°F) | 82°C (180°F) | 150° C (302° F) |

| Rigid | -62°C (-80°F) | 93°C (200°F) | 150° C (302° F) |

It's important to select the appropriate type of polyurethane for your specific temperature requirements to ensure optimal performance and longevity. This broad temperature range makes polyurethane suitable for a variety of applications, including those in automotive, industrial, and consumer products, where both flexibility at low temperatures and stability at higher temperatures are required.

What Happens if Polyurethane is Used Outside of its Designated Temperature Boundaries?

If polyurethane is used outside of its designated temperature boundaries, its performance and properties may be compromised. At low temperatures, polyurethanes may become brittle, hard, and even crack. At high temperatures, polyurethanes may degrade and lose mechanical properties. Using polyurethanes outside of designated temperature boundaries potentially affects the reliability, safety, and lifespan of the application.

What is the Temperature Range for PTFE Films?

Polytetrafluoroethylene (PTFE) films are known for their exceptional temperature resistance.

| Min. | Max. | Short-term Exposure (Max.) | |

|---|---|---|---|

| Skived PTFE Film | -200°C (-328°F) | 260°C (500°F) | 300°C (572°F) |

| ePTFE (Expanded PTFE) | -200°C (-328°F) | 260°C (500°F) | 300°C (572°F) |

PTFE films can handle even higher temperatures for short periods without significant degradation.

Like silicone chemistries, this broad temperature range makes PTFE films suitable for a wide variety of demanding applications, including those in the aerospace, chemical processing, electrical industries, and wire and cable.

What Happens if PTFE is Used Outside of its Designated Temperature Boundaries?

Using PTFE outside of its temperature boundaries can lead to material degradation, loss of mechanical properties, and failure at high temperatures. At low temperatures, PTFE may become brittle and lose its flexibility. Using PTFE outside of its temperature boundaries may compromise its reliability and performance, potentially causing safety issues and reducing the lifespan of the application.

What is the Temperature Range for UHMW-PE Films?

Ultra-High Molecular Weight Polyethylene (UHMW-PE) skived films have excellent temperature resistance properties, although those properties are not as extreme as those of some other high-performance plastics like PTFE.

| Min. | Max. | Short-term Exposure (Max.) | |

|---|---|---|---|

| UHMW- PE Film | -200 °F (-328°F) | 93°C (200°F) | 100°C (212°F) |

UHMW-PE skived films are valued for their high impact strength, excellent abrasion resistance, and low coefficient of friction, making them suitable for various industrial applications. However, for applications requiring exposure to higher temperatures, other materials like PTFE may be more appropriate.

What Happens if UHMW is Used Outside of its Designated Temperature Boundaries?

Using UHMW at high temperatures can cause the material to soften, deform, burn, or catch fire. 93°C (200°F) is the recorded heat distortion temperature for many UHMW films, the temperature at which the material starts to deform under a load. At low temperatures, the material can become brittle, crack, and be less abrasion resistant. Using UHMW outside of recommended boundaries affects the performance, reliability, and lifespan of UHMW in an application.

What are the Temperature Ranges for Rogers Corporation Elastomeric Materials?

Below are the general temperature ranges for our elastomeric material product lines. Please note that this is a guideline. Actual temperature ranges for specific materials will vary.

| Rogers Corporation Material Offering | Typical Range | Intermittent Exposure |

|---|---|---|

| oC oF |

oC oF |

|

| BISCO® Silicones | -55 to 200 -67 to 392 |

225 437 |

| ARLON® Industrial Silicones | -57 to 232 -70 to 450 |

300 572 |

| PORON® Polyurethanes | -40 to 90 -40 to 194 |

121 250 |

| DeWAL® PTFE | -100 to 260 -148 to 500 |

260 500 |

| DeWAL® UHMW | -120 to 85 -184 to 185 |

95 203 |

Where Do I Find Temperature Values for a Specific Material?

- From the Rogers Corporation home page, navigate to the Products tab at the top of the page. Under the Elastomeric Materials Solutions column on the far right, select the Product Family of interest (PORON Industrial Polyurethanes, ARLON Silicones, etc).

- On the Product Family page, select the specific product offering of interest.

- On the product offering page, scroll down to the Downloads section. Under the Data Sheet heading, you will see all available Technical Data Sheets that can be downloaded for future use.

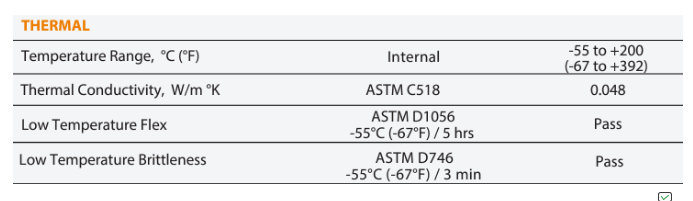

- In the Technical Data Sheet, look for the Thermal or Temperature Resistance section. It may look similar to the image below (source: BISCO Technical Data Sheet). The specification is on the left, and temperature values are on the right.

- You can also find temperature values by reviewing the appropriate Product Properties Guide:

Key Points

- Temperature impacts a material’s properties, so it is important to choose the right temperature rating to ensure safety, reliability, and optimal performance for your product.

- While it is good to know the general temperature ranges for common materials such as silicone, polyurethane, UHMW, and PTFE, you should always refer to specific product pages for accurate temperature values.

- Using materials outside their designated temperature ranges may lead to degradation in mechanical properties, reduced elasticity, cracking, and potential failure, compromising performance and safety.

- Contact a Rogers Sales Engineer to discuss your temperature needs.

Related Content

- Simplify Your Material Search with the New Rogers Material Navigator Tool

- The Ultimate Guide to Compression Force Deflection + Free Tool

- Everything You Need to Know About Compression Set for Elastomeric Foam Materials

Published on Apr 02, 2025