Published

by Rogers Corporation

Elastomeric Material Solutions

As servers, EV modules, and energy storage systems become more compact and powerful, engineers face a recurring challenge: how to manage tight tolerances and protect sensitive components inside densely packed assemblies. The wrong gap-filling material can overstress boards, crack solder joints, or leave uneven spaces that compromise reliability. At the same time, more industries now require materials that meet stringent flame safety standards such as UL 94 V-0.

Finding a foam that delivers both soft compressibility and V-0 compliance has not been easy. Traditional flame-rated foams often trade flexibility for safety. PORON® 40V0 polyurethane foam is designed to close that gap, giving engineers a material that simplifies design without sacrificing compliance.

Why Compressibility Matters in Electronics

In high-density designs, the compressive behavior of a foam can determine whether a system passes qualification testing. Engineers must account for:

- Tolerance absorption. High compressibility allows the foam to adapt to uneven gaps and dimensional variation without forcing the assembly.

- Component protection. Softer foams reduce localized stress that can damage solder joints, connectors, or thin PCB substrates.

- Predictable performance. A stable compression curve provides a clear design window, helping engineers avoid over- or under-compression.

- System optimization. Lower required force means housings, fasteners, or clamps can be lighter and simpler.

Mechanical Profile of PORON 40V0 Polyurethane Foam

PORON 40V0 foam is engineered to combine softness with safety certification:

- Density: 11 pcf, providing a softer profile than most V-0 polyurethane foams.

- Flame Rating: Certified UL 94 V-0 down to 3 mm thickness.

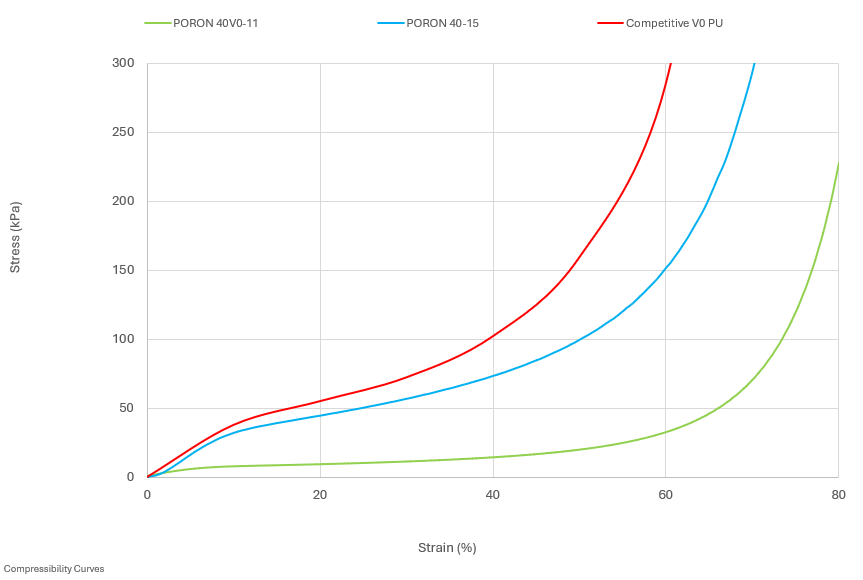

- Compression Behavior: Gradual load increase allows predictable gap-filling across a wide range.

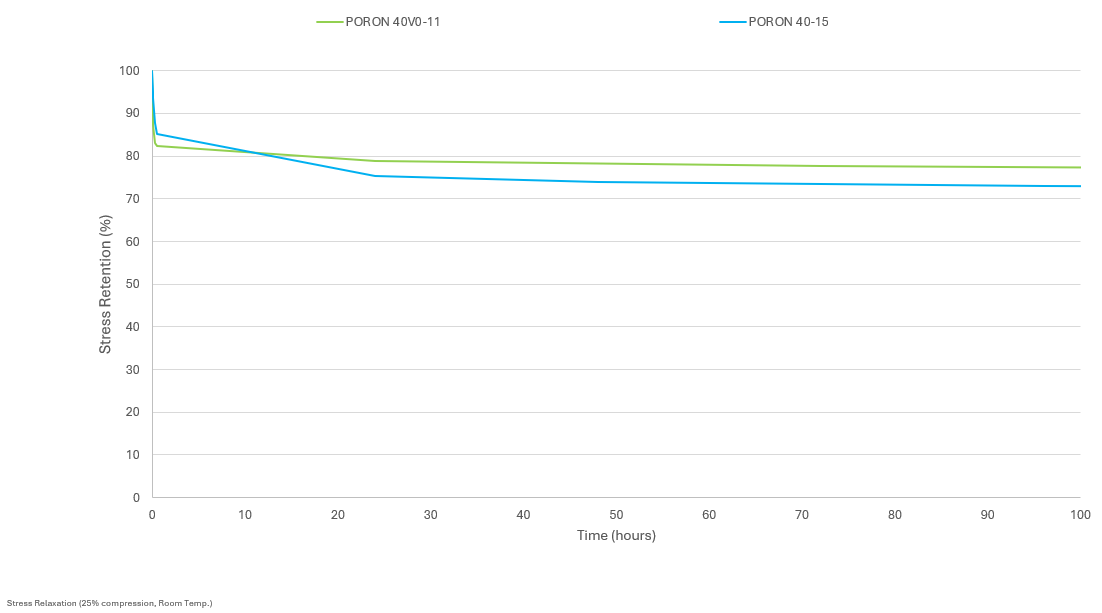

- Stress Relaxation Resistance: Maintains spring force over time to prevent premature seal failure.

Compressibility Curve

Stress Relaxation Curve

Applications That Benefit from High Compressibility

- Data centers: Protecting server boards and modules while filling tolerances in confined housings.

- EV control modules: Cushioning connectors and electronics where space is tight and vibration is constant.

- Battery Energy Storage Systems (BESS): Gap pads that maintain V-0 compliance while accommodating module variability.

- HVAC electronics: Seals that fit variable tolerances while meeting flame resistance requirements.

Design Benefit Summary

| Design Challenge | Why Compressibility Matters | How PORON® 40V0 Foam Helps |

|---|---|---|

| Uneven or variable gaps | Needs to absorb tolerances without excessive force | Soft formulation adapts to tight assemblies |

| Sensitive components (boards, joints) | Risk of cracked solder joints or bent connectors | Lower compression force protects components |

| Long-term sealing performance | Stiffer foams can lose spring force and collapse | Excellent stress relaxation resistance maintains sealing |

| Flame safety compliance | Softer foams rarely achieve UL 94 V-0 | Certified UL 94 V-0 down to 3mm thickness |

Key Takeaway

In today’s compact electronic assemblies, compressibility is a core design parameter, not a secondary property. Choosing a foam that balances softness with flame compliance helps engineers reduce stress on delicate components, manage tolerances, and maintain reliability over time.

PORON 40V0 material provides this balance by combining UL 94 V-0 certification with a soft, compressible profile that engineers can trust for gap-filling in demanding environments.

Learn more about PORON 40V0 foam or request a sample to evaluate the material in your application.

Published on Sep 17, 2025