Published

by Rogers Corporation

Enclosure Institute, Elastomeric Material Solutions

Welcome back to the Enclosure Institute™, where we cover all aspects of enclosure design and sealing solutions. In this second blog, we dive into enclosure ratings and explain the global standards that ensure safety, performance, and compliance.

Disclaimer: While this series provides valuable guidance on enclosure design and material selection, every application is unique. We encourage you to contact the Marian team directly for tailored recommendations and expert support.

Enclosures are essential in industrial, electrical, and electronic applications by protecting critical components from environmental hazards and ensure safe, reliable performance. From shielding sensitive electronics against dust, water, or extreme conditions to preventing costly failures, designing the right enclosure is vital.

Globally recognized standards—such as NEMA, UL, CSA, and IEC—offer a unified framework to evaluate enclosures, ensuring they meet safety, environmental, and performance needs across industries.

Let’s explore these key standards, highlight their differences, and explain their importance in helping you make the best choice for your application.

What are Enclosure Ratings?

Enclosure ratings are important because they directly affect the safety and protection of sensitive internal components within the enclosure and ensure reliable performance in various conditions.

Standards are written as application descriptions and provide expected performance guidelines, which provides design engineers with a common language for comparison.

Four types of gaskets – strip, die-cut, form-in-place, and bulb extrusion – help seal out dust and liquids according to the requirements of four of the most common standards.

These standards include:

- National Electrical Manufactures Association - NEMA®

- Underwriters Laboratory – UL Solutions®

- Canadian Standards Association – CSA®

- International Electrotechnical Commission – IEC®

Overview of Key Standards

Let’s dive deeper into each of the common standards.

NEMA - National Electrical Manufacturers Association

Website: www.nema.org

Find them on LinkedIN: www.linkedin.com/company/nema

NEMA, founded in 1926, is an ANSI-accredited (American National Standards Institute) organization made up of engineers, electrical experts, leaders in the business community and other technical subject matter experts.

NEMA sets performance-based standards for enclosures in U.S. industrial and electrical applications, focusing on protection against water, dust, and corrosion to ensure reliable equipment operation.

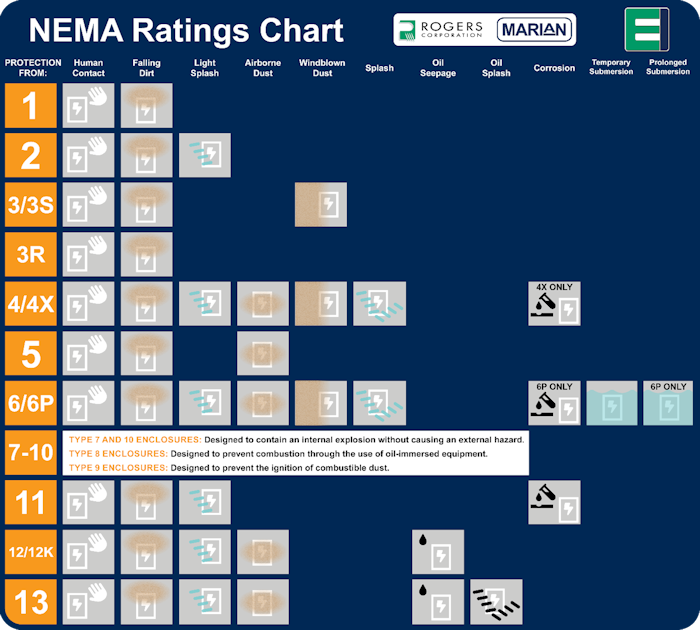

Ratings range from 1 to 13, with NEMA ratings 12 and 13 suited for indoor use and NEMA 3, 4, 4X, 6, and 6P ratings designed for outdoor environments which require additional resistance to harsh conditions.

For example, a NEMA 4X enclosure is excellent for outdoor electrical control panels exposed to harsh weather and corrosive environments, such as in marine or chemical processing industries.

Unlike UL, which mandates third-party testing, NEMA allows manufacturers to self-certify compliance, placing responsibility on them to meet performance criteria. NEMA also contributes to global standards by shaping U.S. input on IEC standards, bridging domestic and international requirements.

UL Solutions - Underwriters Laboratories

Website: www.ul.com

Find them on LinkedIN: https://www.linkedin.com/company/ulsolutions

You are likely familiar with UL from the UL certification mark on many home appliances and devices. Founded in 1894, UL Solutions, is a global leader in testing, inspection, and certifications, as well as advisory offerings across a range of industries.

For enclosures, UL provides widely recognized North American safety certifications, focusing on rigorous testing to ensure safety and performance under specific conditions. While UL ratings align closely with NEMA standards, they place a stronger emphasis on hazard prevention, such as fire risk and ingress protection, through third-party testing and certification.

For example, UL 50 specifies requirements for enclosures to ensure reliable protection and safety in electrical applications, making UL a trusted standard for environments where verified performance is critical.

CSA - Canadian Standards Association

Website: www.csagroup.org

Find them on LinkedIN: https://www.linkedin.com/company/csa-group/

The CSA serves as the Canadian equivalent to UL and NEMA, ensuring enclosures meet stringent safety and performance requirements.

While CSA standards are often harmonized with North American guidelines, they may include regional variations to address specific Canadian regulations or conditions. Like UL, CSA focuses on thorough testing and certification, providing confidence that enclosures will perform reliably in their intended applications.

IEC - International Electrotechnical Commission

Website: www.iec.ch

Find them on LinkedIN: https://www.linkedin.com/company/iecstandards/

IEC was founded in 1906 and is a global organization that develops and publishes international standards for all electrical, electronic, and related technologies. These standards serve to ensure safety, efficiency, and interoperability between devices and systems. The work of the IEC covers a wide range of technologies from power generation, transmission, and distribution to home appliances, office equipment, semiconductors, fiber optics, batteries, solar energy, nanotechnology, and many others.

For enclosures, the IEC sets global standards through its IP (Ingress Protection) Code, which measures protection against dust and water, expressed as IP-XX (e.g., IP54, IP65, IP67). Unlike NEMA, which also accounts for environmental factors like corrosion, IP codes focus solely on ingress protection, allowing limited water entry if it doesn't affect performance.

Defined in IEC Publication 60529, the system classifies protection with two digits: the first for solids (e.g., dust) and the second for water. While NEMA standards, such as NEMA 250, test for broader conditions like rust and oil, IEC ratings provide a global, standardized approach for ensuring reliable performance in environments where ingress protection is critical.

Comparing NEMA and IP Ratings

While both NEMA and IP ratings evaluate enclosure performance, they focus on different priorities. Engineers should choose the rating system that aligns with their specific application and environment. Here’s a quick comparison:

NEMA:

- Includes environmental factors like corrosion, oil, or gasket performance.

- Generally requires strict protection and prohibits any ingress.

IP:

- Focuses specifically on ingress protection against solids and liquids.

- Allows limited ingress if performance is not impacted.

| NEMA Enclosure Type Number | IEC Enclosure Designation |

|---|---|

| 1 | IP10 |

| 2 | IP11 |

| 3 | IP54 |

| 3R | IP14 |

| 3S | IP54 |

| 4 and 4X | IP56 |

| 5 | IP52 |

| 6 and 6P | IP67 |

| 12 and 12K | IP52 |

| 13 | IP54 |

Why These Ratings Matter

Selecting the proper enclosure standard is critical for engineers to ensure equipment reliability, safety, and compliance across diverse applications. Industry requirements often dictate which standard to follow—NEMA ratings are widely used in North America, while IEC IP codes are preferred for global projects. Additionally, the enclosure must be suited to specific environmental conditions, such as protection from water submersion, dust, or corrosive elements.

Compliance with safety and certification standards like UL or CSA is equally important to prevent risks like electrical hazards or fire. For example, using an enclosure with an insufficient rating—such as installing a NEMA 12 enclosure outdoors instead of a NEMA 4X—could result in water ingress during heavy rain, causing electrical failure, costly downtime, and potential safety hazards.

Ultimately, these standards along with the application function and requirements help determine which materials are needed for the custom components within your enclosure to ensure an adequate seal.

Proper selection ensures the enclosure meets the demands of its environment while safeguarding critical components.

| Standard | Org Type | Region | Criteria | Use Case Examples | Certification Type |

|---|---|---|---|---|---|

| NEMA | Industry Association | U.S. | Performance-based (dust, water, corrosion) | Industrial control panels, outdoor enclosures | Self-certified by manufacturers, device-level |

| UL | Independent Safety Organization | North America | Safety (fire risk, ingress protection) | Electrical enclosures requiring verified safety | Third-party testing, device-level |

| CSA | Standards Organization | Canada | Safety and performance | Applications requiring regional compliance | Third-party testing, device-level |

| IEC (IP Code) |

International Standards Body | Global | Ingress protection (dust and water) | Automotive, aerospace, and global projects | Standardized globally, device-level |

Enclosure Certifications vs. Material Compliance

Standards like NEMA, UL, CSA, and IEC (IP Code) apply at the device level, meaning they certify fully assembled enclosures (and not individual materials). Materials are not certified to IPX ratings or NEMA enclosures, but they are designed to support compliance by providing ingress protection, fire resistance, and long-term durability. When properly integrated, materials can help enclosures meet these critical standards.

For guidance on selecting the right materials for your enclosure design, contact Marian.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™—a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for The Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

- Fundamentals of Enclosures: Applications, Sealing, and Protection

- 8 Key Considerations for Designing Reliable Seals and Gaskets

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Published on Apr 30, 2025