Published

by Rogers Corporation

Elastomeric Material Solutions

Since the 1960s, many material suppliers of foam and sponge products have used density to help describe material firmness.

Rogers material experts, however, believe that compression force deflection (CFD) is a more accurate method to categorize the firmness of BISCO® cellular silicone and PORON® polyurethane foams.

Let's review the fundamentals of density and firmness, how they’re measured, and why both are important in elastomeric material selection.

Density

What is Material Density, and Why is it Important?

Material density is simply a measurement of mass per unit of volume. It’s a key factor in determining whether a foam is suitable for specific applications:

- High-density materials are heavier, making them ideal for applications requiring durability and/or sound blocking. However, if weight is a critical factor, such as in aircraft design where it impacts fuel consumption, lower-density materials may be preferred. High-density foams and solids can act as effective sound barriers.

- Low-density materials are lighter and offer better cushioning properties, making them ideal for applications where weight reduction is a key consideration. However, they may not provide the same level of durability or sound-blocking capability as higher-density materials. Low-density foams are excellent for absorbing sound (acoustic absorption).

High-Density Foams vs Low-Density Foams Summary

High-Density Foams:

- Heavier and more durable

- Ideal for sound blocking and structural support

- Commonly used in automotive soundproofing or industrial gaskets

Low-Density Foams:

- Lighter and better at cushioning

- Ideal for weight-sensitive applications like aircraft design

- Excellent for acoustic absorption

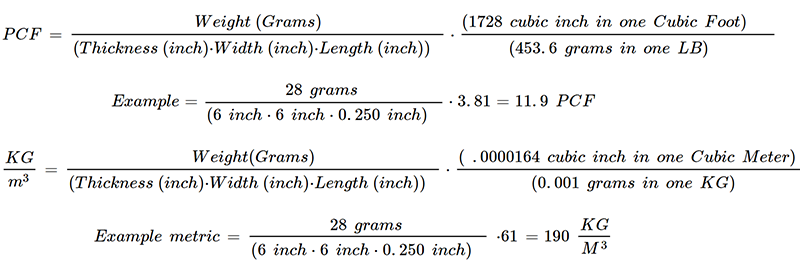

How is Density Measured for Foam and Sponge Materials?

The density of foam and sponge material is typically measured in pounds per cubic foot (PCF) or kilograms per cubic meter (Kg/m³). This is done by measuring the weight of the material and dividing it by the materials volume.

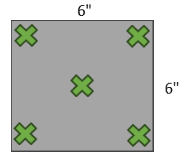

For example, here is how to calculate the density of a BISCO material:

- Cut a 6" x 6" sample using a calibrated rule from a piece of material.

- Measure the material thickness using a drop gauge (which does not exert pressure on the surface). Use a 1" measuring head to measure five spots, the four corners, and the center of the sample, as designated in the image above.

- Weigh the sample on a calibrated scale.

- Calculate the density of the material using the following formula to get PCF:

Firmness

What is Material Firmness, and Why is it Important?

Material firmness refers to how the foam or sponge will change when compressed by a force. It is critical to consider for achieving optimal performance in applications.

Firmness determines whether a foam can:

- Maintain a seal under pressure.

- Prevent deformation in surrounding materials like metal or plastic.

- Provide cushioning or structural integrity based on the application.

Material firmness can be classified from ultra-soft to very firm.

- Overly-firm materials may cause deformation in metals or plastics.

- Overly-soft materials might fail to seal effectively against dust or liquids.

If the material is too firm, a part may deflect by creating too much force, making the part bow and distort if it is a metal or crack if it is a plastic. If the force is too soft, it may not create the desired sealing or gap filling, leaving areas for the ingress of dust and liquids.

How is Firmness Measured?

The firmness of foams is measured by squeezing a 1” diameter piece of foam between two plates and noting how much pressure (stress) causes the foam to compress and by what percent (strain). A curve of stress versus strain can be developed, and most materials are rated by how much pressure it takes to compress the foam by 25%. A foam that takes less pressure to compress it by 25% is softer than one that takes more pressure. BISCO silicones use ASTM D1056, and PORON polyurethanes use ASTM D3574 as test methods.

What Material Firmness is Right for my Application?

Selecting the right material firmness depends on factors like gasket design and environmental exposure. How much and with what intensity is the application exposed to dust and liquids?

Here's a quick guide to choosing the right material firmness:

Soft Foams

- Best for dust sealing and low-closure force applications.

- Suitable for irregular surfaces, where the foam fills small gaps or voids.

Firm Foams

- Ideal for preventing liquid ingress in gaskets or seals.

- Provides enhanced sealing and durability for high-pressure applications.

When in doubt, start with a medium firmness foam, which often provides a balance of sealing performance and minimal stress on mating surfaces.

The details:

Softer materials are more forgiving and are ideal for applications requiring low closure force and dust sealing. Softer materials also work well where the surface may be irregular since they can fill voids and small gaps.

Firmer materials offer more enhanced sealing capabilities since both surfaces have additional force. This keeps any dust or liquid from going around the mating surfaces of the gasket and material substrate.

We recommend testing a medium firmness if you’re unsure if a soft or firm material would work better. Medium firmness is often tested first if firmness requirements are unknown because it offers good sealing performance without creating too much stress on mating surfaces. Essentially, medium firmness captures the best of both worlds.

Firmness versus Density for Cellular Materials

Are Firmness and Density Correlated?

It is a common misconception that as a cellular material's firmness increases, so does its density.

However, foam or sponge firmness and density are not necessarily correlated, as a low-density material may be firm while a high-density material can be soft.

Density and firmness are independent of each other and must be evaluated separately when selecting a foam or sponge for your application.

A product's firmness is normally associated more with a particular formulation or manufacturing process, allowing companies to lower or increase the density and compression force independently.

How Do I Find a Material’s Firmness or Density?

The best way to find a material’s firmness and density is to look at the material’s technical data sheet. Both the density and firmness should be listed.

For Rogers materials, go to the material’s product page and look under the “Downloads” > “Data Sheets” section.

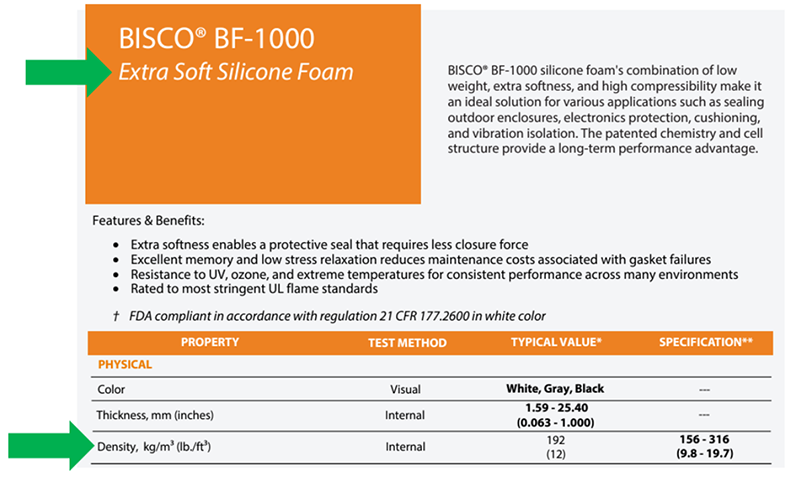

For example, BISCO® BF-1000 Technical Data Sheet looks like this:

Tools to Help You Choose the Right Foam

Our website offers various tools to help you determine which product series will best suit your unique application.

- Product Properties Guide: Quickly search and sort through various products by material property.

- Compression Force Deflection Tool: Sort and compare products based on their respective stress-strain data.

- Application Design Tool: Select an application and filter further by product properties and specification.

Key Points

- Density measures mass per unit volume and affects durability, weight, and acoustic properties.

- Firmness indicates how foam compresses under force, crucial for sealing and structural integrity.

- Density and firmness are independent properties that must be evaluated separately.

- Always consult with your Rogers Sales Engineer for guidance on the best material choice.

Related Content

- The Ultimate Guide to Compression Force Deflection + Free Tool

- Top 7 Unique Silicone Advantages You Can't Ignore

- The Engineer's Toolkit: 8 Best Tools for Effective Material Selection

Published on Jan 17, 2025