Published

by Rogers Corporation

Enclosure Institute

Welcome back to The Enclosure Institute™—your go-to resource for designing better-sealed, longer-lasting enclosures.

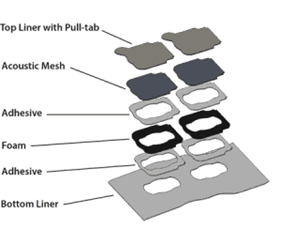

In this blog, we’re tackling a deceptively complex topic: pressure-sensitive adhesives (PSAs).

These thin layers do a lot of heavy lifting, especially in multi-layer components like gaskets, filters, and EMI shields. The wrong adhesive can lead to poor bond strength, delamination, or premature failure.

Image property of Marian Inc

While this isn’t a necessary step for all applications, it’s important to understand the things you should keep in mind if the application requires an adhesive layer.

In this guide, you’ll learn how to:

- Match adhesives to foam and enclosure materials

- Account for peel, shear, and environmental stresses

- Avoid common PSA pitfalls during assembly

- Choose between rubber, acrylic, and silicone PSAs

- Improve manufacturability and product lifetime

Let’s break down how to select the right PSA, starting with its job in your design.

Key Considerations When Choosing a PSA for Enclosure Components

1. What Does Your Adhesive Need to Do?

Understand the Purpose of the Adhesive

PSAs can do more than just stick things together. The first step is defining what the adhesive needs to do in your application. PSAs serve several possible roles:

- Secure placement during assembly—either manually or with automation

- Act as a stiffener, giving flexible foams added dimensional stability (common with double-sided adhesives)

- Allow repositioning, using low-tack PSAs that can be removed and reapplied without damage—similar to a Post-it® Note

- Enable flexibility, where a transfer adhesive is used to avoid restricting the foam's ability to flex, turn, or bend

- Withstand dynamic compression, when the gasket is compressed, released, and re-compressed over time

Image property of Marian Inc

Unsupported gasket

Image property of Marian Inc

Same gasket but supported with adhesive to help keep structure

The more dynamic, high-vibration, or high-temperature your application, the more robust the PSA needs to be—often requiring higher adhesion levels than a standard static seal. A PSA that performs well in a one-time compression may still fail in a dynamic enclosure where the gasket is repeatedly compressed and released. Consider the long-term mechanical and environmental stresses acting on the adhesive, not just ease of assembly.

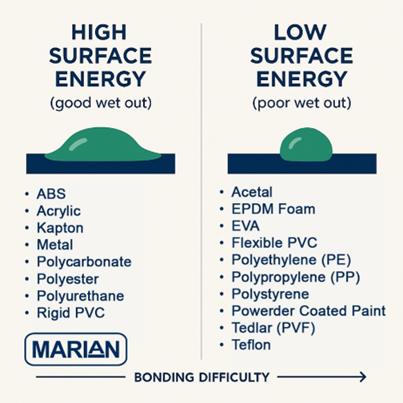

2. Struggling to Bond to Painted Metal or Plastics? It’s All About Surface Energy

Match the PSA to the Bonding Surface

When it comes to PSA performance, what you’re sticking to matters just as much as what you’re sticking with.

The bond strength between your adhesive and the enclosure depends heavily on surface energy—or how well the adhesive can “wet out” and make contact with the substrate. Common enclosure substrates include:

- Metals like painted steel or anodized aluminum

- Plastics like ABS, polycarbonate, or nylon

- Coated or treated surfaces

- Porous, rough, or pitted finishes

- “As cast” surfaces, which may retain irregular textures or residues

- Smooth surfaces, which can be easier to bond but may require clean prep

If you're bonding to a low surface energy (LSE) material (like silicone rubber or polyethylene), standard acrylic adhesives may not hold well. In these cases, your options include:

- Using a silicone-based PSA, which bonds to LSE materials

- Treating the surface (example: corona or plasma treatment) so a more economical acrylic PSA can be used

Image property of Marian Inc

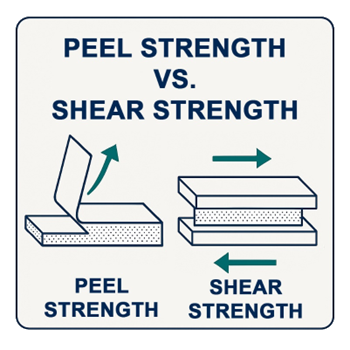

3. Is Your Adhesive Failing in the Field? Check for Peel and Shear Stress

Account for the Stresses Acting on the Bond

Not all stresses are created equal. Even if your adhesive bonds well initially, the real test is whether it can handle the mechanical stresses your enclosure will encounter.

There are two main stress modes to understand:

- Peel stress pulls the component away from the surface, usually at an angle.

It’s like peeling the skin off a banana—lift from one edge and the entire bond can start to give. This is especially common at unsupported corners or tabs where stress concentrates. - Shear stress slides the bonded surfaces across each other, parallel to the adhesive layer.

Imagine a gasket compressed between two surfaces that shift slightly over time—like during vibration or thermal cycling.

Image property of Marian Inc

Some adhesives are engineered for strong peel resistance, while others excel at shear strength. Understanding which type of stress is present in your application will help guide adhesive selection.

4. Will Heat, Moisture, or UV Exposure Break Down Your Bond?

Consider the Environment

Environmental exposure is one of the most common reasons PSAs fail over time, especially in outdoor or industrial enclosures.

Before you select an adhesive, ask yourself:

- What are the maximum and minimum temperature in use?

Some adhesives lose tack at cold temps or soften at high heat. - Will it be exposed to moisture, humidity, or pressure changes?

Water intrusion or condensation can weaken bonds. - Are there chemicals, oils, or cleaning agents present?

Acrylic adhesives typically hold up well to solvents, rubber-based options often do not. - Will there be UV exposure or direct sunlight?

UV light can degrade many rubber PSAs quickly, while acrylic and silicone PSAs offer improved stability.

Matching your PSA chemistry to your environment matters. For example:

- Rubber PSAs: Low cost but poor resistance to UV, solvents, and heat

- Acrylic PSAs: Ideal for outdoor or long-term use—excellent UV and solvent resistance

- Silicone PSAs: Extreme durability in high-temp or chemically harsh environments

5. What Type of PSA Should You Use? Rubber, Acrylic, or Silicone?

In general, there are three basic types or families of adhesives in pressure sensitive adhesive: rubber, acrylic, and silicone. Here’s a quick breakdown of their chemistries and how they perform.

| PSA Type | Key Strengths | Best For | Limitations |

|---|---|---|---|

| Rubber-Based |

|

|

|

| Acrylic-Based |

|

|

|

| Silicone-Based |

|

|

|

However, corona treatment can be used to raise the surface energy of silicone materials. This allows you to use acrylic PSAs, which offer strong adhesion, lower cost, and broader versatility compared to silicone adhesives without sacrificing performance. This is a capability of both Marian and Rogers, so contact us to learn more how this process can benefit your applications.

Images property of Marian Inc

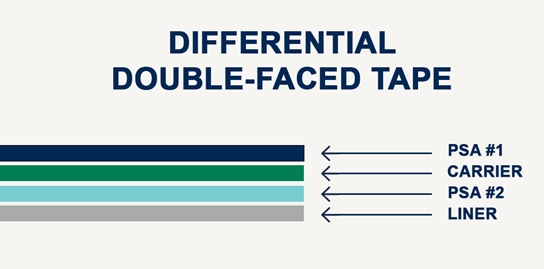

6. How PSA Construction Affects Flexibility, Fit, and Function

Adhesive Construction: Double-Faced Tapes

Double-faced (or double-liner) tapes are the most common PSA construction used in lamination for enclosure components. These tapes feature adhesive layers on both sides of a central carrier, which provides dimensional stability and ease of handling during assembly.

Carrier materials typically include:

- Polyester films

- Paper fibers

- Fabrics

- Foams

In many designs, the same adhesive chemistry is applied to both sides of the carrier. However, differential double-faced tapes are also available, combining two different adhesive types—such as rubber/acrylic or acrylic/silicone—to optimize bonding between dissimilar substrates.

This construction allows engineers to fine-tune adhesion performance on each side of the component, improving compatibility with both the gasket material and the enclosure surface.

Image property of Marian Inc

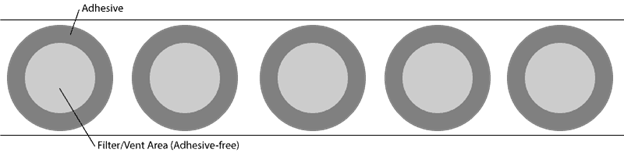

Geometry of the Adhesive Layer: Full Coverage vs. Zone Lamination

Most gaskets and cushioning components use full-coverage adhesive layers. It’s easy, fast, and reliable for sealing.

However, adhesive placement doesn’t need to follow a one-size-fits-all pattern.

In some applications, such as vents or filters, a full adhesive layer may interfere with airflow or reduce performance of the functional layer. In these cases, the adhesive can be cut separately and applied only where needed, in a method known as zone lamination.

Zone lamination allows for strategic placement of adhesive, helping to preserve function while minimizing material waste and optimizing performance.

Images property of Marian Inc

7. Protective Liners and Part Presentation for Fast, Clean Assembly

The adhesive might be right, but if the liner is hard to remove or doesn’t match your assembly process, it can cause slowdowns or even part damage.

When selecting or designing adhesive-backed components, think about how your team will handle and apply them.

Key Factors to Consider:

- Assembly method:

- Manual placement requires easy liner removal (think pull-tabs)

- Automated systems often benefit from kiss-cut parts on a roll

- Liner type and shape:

- Extended tabs or split liners speed up manual handling.

- Custom die-cut liners can align with complex part shapes

- Presentation format:

- Kiss-cut on roll: Fastest for automation or high-volume manual assembly

- Individual parts with pull-tab: Ideal for slower or more delicate placement

- Sheet or nested formats: Efficient for prototyping or low volume builds

Images property of Marian Inc

8. Availability & Cost

With so many high-performance adhesives on the market, it’s easy to overdo it, but s electing a PSA with specs beyond what your application needs can drive up cost without improving performance.

At the same time, skipping cost or sourcing considerations early on can lead to delays, limited availability, or revalidation headaches later.

What to Watch For:

- Don’t pay for more than you need:

If your component isn’t exposed to UV, chemicals, or flex, you probably don’t need a premium silicone or high-performance acrylic. - Understand sourcing constraints:

- Some adhesives require large minimum order quantities (MOQs)

- Others may not be stocked or available in every region

- Lead times can vary drastically between suppliers and product families

- Global program:

For multi-site or international production, adhesive availability across regions matters. If your PSA isn’t globally stocked, it could impact launches or consistency across builds.

Marian’s PSA Expertise

As a global leader in converting and Rogers Preferred Converter, Marian has extensive expertise in adhesive selection, precision converting, and enclosure component design. We’re a Preferred Converter for top adhesive brands, including:

- 3M

- tesa

- Polymer Science

- And more

With access to global inventories and engineering support, Marian helps teams prototype, validate, and scale with the right PSA solution for the job.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute™

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™—a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for the Enclosure Institute™?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an Enclosure Institute Essentials Kit upon completion, recognizing your expertise

The Enclosure Institute™ is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design:

Not ready to enroll yet?

Explore more blogs on enclosure design best practices:

- Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

- Fundamentals of Enclosures: Applications, Sealing, and Protection

- 6 Reasons Why Gaskets Fail: Materials and Environment

Your Trusted Partners in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Contact Marian

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Published on Jun 25, 2025

Institute Insight

Institute Insight