Published

by Rogers Corporation

Elastomeric Material Solutions, Enclosure Institute

Welcome back to the Enclosure Institute™, where Marian and Rogers partner with engineers to master enclosure design and precision sealing solutions. From material selection to converting practices, we share insights that support long-term reliability and performance.

When it comes to sealing an enclosure, engineers have many options, and each comes with trade-offs. Depending on the design priorities, you may need the least expensive seal, the longest lasting seal, one that allows for repeated opening and closing, or one that simplifies manufacturing.

Choosing the right gasket technology is critical to balancing performance, manufacturability, and total cost of ownership.

In this guide, we compare four common sealing methods—O-rings, die cut gaskets, cure-in-place, and foam-in-place— and where high-performance foams can offer unique advantages in demanding enclosure applications.

O-Ring Seals

O-rings are one of the most familiar gasket solutions, commonly used in enclosures that need to be opened and resealed multiple times.

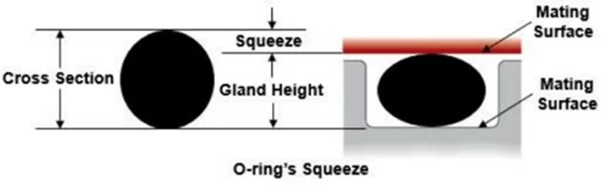

- Design Fit: Their generally round shape makes them best for simple closures such as circles and rounded squares. They are most effective when placed into a channel on the sealing surface, so they should be designed into the enclosure from the very beginning.

- Manufacturing: Produced by molding to standard sizes, or by cutting extruded cord to length and bonding it into a ring shape. Special lengths and thicknesses can be made quickly, often within a week, for prototyping.

- Performance: Frequently made of solid elastomer, which provides a strong long-term barrier against leakage. Excellent sealing if kept clean.

- Cost: Standard O-rings are relatively inexpensive and widely available, making them economical for both low- and high-volume production.

- Reworkability: Easy to assemble into channels, simple to rework, and effective for applications requiring repeated opening and resealing.

Image property of Rogers Corporation

Cross-section of an O-ring showing how squeeze is created within a gland to form a reliable seal between mating surfaces. Image property of Rogers Corporation

Die Cut Foam Gaskets

Die cut foam gaskets are one of the most versatile sealing options and can be tailored to nearly any enclosure shape.

- Design Fit: They are designed for flat sealing surfaces, with no need to build channels into the enclosure. Suitable for non-simple geometries that cannot easily be sealed with an O-ring.

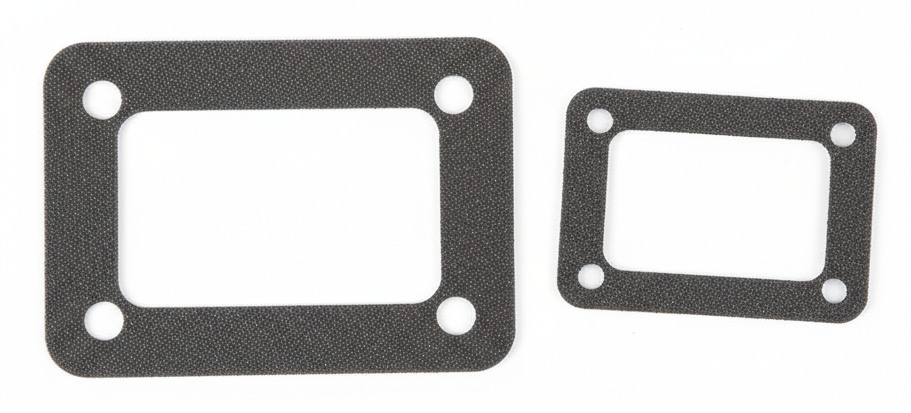

- Manufacturing: Fabricated from sheets of elastomeric foam. Intricate shapes can be produced within hours using low-cost methods like laser or waterjet cutting, making them ideal for rapid prototyping. For higher volumes, die-cutting provides scalability, though it can create waste from the cut-out centers. Nesting patterns or assembling gaskets in multi-piece formats can reduce this waste.

- Performance: When made from high-quality open-cell elastomers such as silicone or polyerethane foams, cut gaskets resist compression set, maintaining their shape under load and supporting reliable long-term sealing. They are also well-suited for enclosures that must be opened and closed repeatedly during their service life.

- Cost: Material costs can be somewhat higher than standard O-rings and die-cutting may introduce waste. However, low tooling costs, rapid turnaround, and scalability often make cut foam gaskets a cost-effective choice across prototype and production volumes.

- Reworkability: Easy to install during assembly, simple to rework, and easy to replace in the field, offering strong serviceability advantages.

Examples of cut foam gaskets produced from elastomeric foam sheets. Die-cut shapes like these are commonly used for flat sealing surfaces in enclosure assemblies. Image property of Rogers Corporation

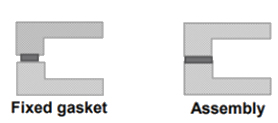

- Gasket Type: A pre-fabricated foam gasket that is fixed to one surface and then compressed during assembly.

- Process: Already manufactured and cut, it is then placed in the enclosure before assembly.

- Key Point: Serviceable and reworkable. Often the best choice when long-term performance and repeat sealing are required.

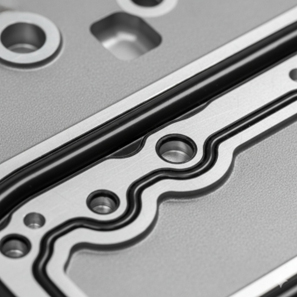

Cure-in-Place (CIP) Gaskets

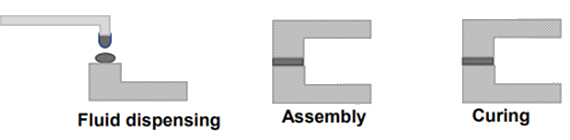

Cure-in-place gaskets are created from liquid elastomers that are dispensed and cured into a solid seal.

- Design Fit: They are typically dispensed directly onto one surface of the seal, then compressed against the mating surface while the material cures. Once cured, the gasket bonds tightly to both surfaces. Well-suited for intricate gasket designs where molded or cut parts may not be feasible.

- Manufacturing: The liquid is dispensed either through catalyzed room temperature vulcanization (RTV) or by curing at elevated temperatures. Dispensing and handling can be automated with robotics, reducing assembly labor. However, the costs of robotics and dispensing must be amortized across many parts to make this approach economically feasible.

- Performance: Because the material starts as a liquid, it adheres well to both surfaces, creating a strong and reliable long-term seal. However, once cured, the seal is fixed and cannot be separated without damage.

- Cost: While labor costs can be reduced through automation, the required robotic dispensing equipment represents a significant capital expense. Additional costs may come from the need to hold assemblies in inventory, sometimes in ovens, while the liquid cures.

- Reworkability: Nearly impossible to rework in manufacturing or the field. If a seal cures incorrectly, the part may need to be scrapped.

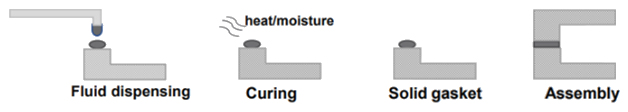

- Gasket Type: A liquid elastomer dispensed directly onto a surface, then cured (by heat or moisture) into a solid gasket before assembly.

- Process: Dispensing → curing → bonded gasket → enclosure assembled.

- Key Point: Creates a bonded seal with strong adhesion but cannot be reworked. Requires controlled curing conditions.

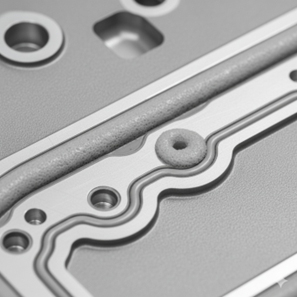

Foam-in-Place (FIP) Gaskets

Foam-in-place gaskets are produced in a process similar to cure-in-place, but with an important difference: the foamed elastomer is cured onto one mating surface first, and the enclosure is assembled later. This is also sometimes called form-in-place gaskets, FIPG.

- Design Fit: Liquid elastomer is dispensed onto one mating surface where it foams and cures, generally at elevated temperature. The second surface is compressed against the cured foam during final assembly.

- Manufacturing: Requires similar capital investment to cure-in-place processes, including dispensing and curing equipment. However, it allows greater logistical flexibility, since mating parts do not need to be assembled during curing and can be joined later at a different time or location.

- Performance: Foam-in-place gaskets typically form closed-cell, free-rise foams that are less resistant to compression set. As a result, they are not ideal for long-term sealing or for applications requiring the enclosure to be opened and resealed.

- Cost: Capital equipment and programming represent a significant upfront expense, but the method can be cost-effective for high volumes and complex gasket geometries.

- Reworkability: Once cured to one part of the enclosure, reworking the seal is difficult. If a gasket is defective, parts may need to be discarded.

- Gasket Type: A liquid elastomer is dispensed onto one surface, then the mating part is assembled immediately and the gasket cures in place with both parts together.

- Process: Dispensing → assembly → curing in position.

- Key Point: Excellent seal adhesion but requires both mating parts to be present during the cure and makes rework nearly impossible.

Cure in place gasket

Foam in place gasket

Choosing the Right Gasket Technology

No single sealing method fits every application. O-rings excel in simple, high-cycle designs. Cut foam gaskets balance flexibility and reworkability. Cure-in-place seals provide exceptional adhesion for complex geometries but sacrifice serviceability. Foam-in-place gaskets streamline production for high-volume assemblies.

For demanding environments where long-term compression recovery, durability, and ease of replacement are key, high-performance foams such as BISCO® silicone and PORON ® polyurethane materials often deliver the best balance of reliability and practicality.

Comparison of Gasket Technologies

| Gasket Type | Design Fit | Manufacturing | Performance | Cost | Reworkability | Best For |

|---|---|---|---|---|---|---|

| O-Ring | Simple, round geometries; requires gland/channel | Molded or cut-to-length | Excellent sealing, reusable | Low | Easy to rework and replace | High-cycle enclosures and standard shapes |

| Die-Cut Foam Gasket | Flat surfaces, any geometry | Laser, waterjet, or die-cut from foam sheets | Good long-term sealing; resists compression set | Moderate | Easy to rework and replace | Custom geometries, prototypes, and field service |

| Cure-in-Place (CIP) | Complex designs requiring precise placement | Liquid elastomer dispensed and cured | Strong adhesion; durable seal | High (due to capital equipment) | Not reworkable | Complex assemblies where seal will not be reopened |

| Foam-in-Place (FIP) | Complex surfaces; allows delayed assembly | Foamed elastomer dispensed and cured on one side | Closed-cell; less compression-set resistance | High (capital equipment, programming) | Difficult to rework | High-volume applications with complex geometries |

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute—a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for The Enclosure Institute?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an exclusive swag box upon completion, recognizing your expertise

The Enclosure Institute is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design.

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Not ready to enroll yet? Explore more blogs on enclosure design best practices:

- Top 8 Best Practices You Need To Know for Enclosure Die-Cut Gaskets

- How To Validate Enclosure Seal Reliability Through 5 Tests

- Expert Tips for Preventing Polymer Degradation in Enclosure Applications

Your Trusted Partner in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Published on Oct 07, 2025

Institute Insight

Institute Insight