Published

by Rogers Corporation

Elastomeric Material Solutions, Enclosure Institute

Welcome back to The Enclosure Institute™, where we explore the principles behind reliable, long-lasting enclosure design.

In this edition, we’re focusing on an often-overlooked aspect of protection: venting.

As enclosures get lighter, thinner, and more complex, proper venting has become essential to maintaining performance and protecting sensitive components from pressure, moisture, and contamination.

Why Enclosures Need Venting

When most people think of an “enclosure,” they picture a large metal box, such as a home circuit breaker panel box, that has a door with a hinge on one side and a latch on the other. But in reality, enclosures are everywhere:

- The sensors and electronics in your car — even the headlight assembly.

- Medical devices like CPAP air channels or diagnostic equipment housings.

- The smart displays that control your home’s appliances or heating systems.

- Every connected device in the IoT ecosystem.

These modern enclosures are rarely made of metal. To reduce cost and weight, manufacturers are increasingly using lightweight thermoplastics. As the walls of these thermoplastic enclosures get thinner, pressure changes and moisture exposure can become critical design challenges. That’s where the importance of venting comes in.

Two Key Purposes of Venting

1. Pressure Equalization

Enclosures must withstand repeated changes in temperature and atmospheric pressure. Without a vent, internal pressure builds up, which stresses joints, seals, and thin plastic walls.

A vent allows the enclosure to equilibrate the pressures inside and outside the enclosure, removing stress from the thin materials from which the enclosure is made.

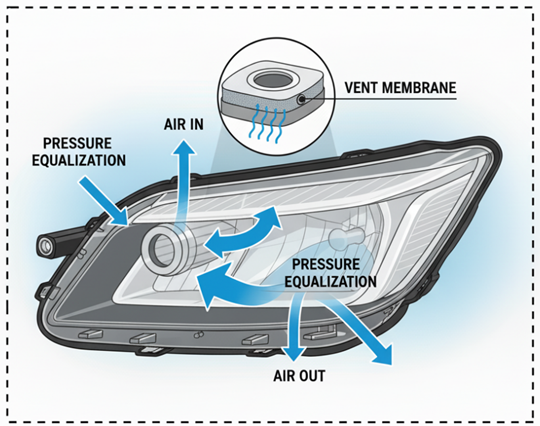

Take an automotive headlight, for example. The enclosure serves both as the housing and the optical lens, typically molded from a high-strength, thin thermoplastic to minimize vehicle weight. As the vehicle climbs to higher elevations or the LED bulb heats the internal air, the pressure inside rises.

A pressure equalization vent allows the enclosure to “breathe,” balancing internal and external pressures so the lens doesn’t deform, crack, or leak over time.

Pressure equalization of a headlight. Image generated by Gemini.

2. Moisture Management

Even when sealed, enclosures can trap moisture from ambient humidity, condensation, or outgassing of materials. Over time, that trapped moisture can fog lenses, corrode electronics, or degrade adhesives.

Vents manage this by allowing moisture vapor to escape while keeping contaminants like water, dirt, and oil out.

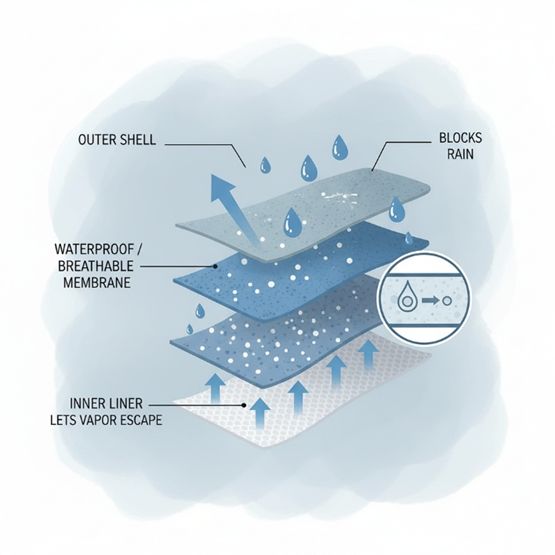

Let’s look at the car headlight example again. Thermoplastics can absorb water, which can make its way into the enclosure, and fog the lens of the headlight. Using the heat of the LED bulb, this can be forced out through the vent as water vapor, much like good rain gear that allows your body's moisture to escape while keeping you dry from the rain.

Rain gear layers. Image generated by Gemini.

Types of Vents Used in Enclosure Design

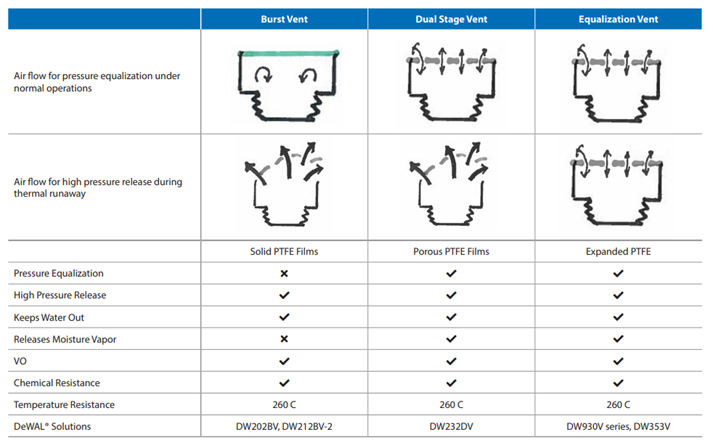

Engineers typically use one of three types of vents, each designed for a specific performance scenario:

| Vent Type | Construction | Function | Typical Use |

|---|---|---|---|

| Burst Vent | Solid membrane | Stays sealed during normal operation; bursts under high pressure to release gas | Thermal runaway protection in battery packs or sealed modules |

| Pressure Equalization Vent | Expanded PTFE (ePTFE) membrane | Allows continuous airflow for pressure equalization while blocking water and particulates | Headlights, outdoor electronics, sealed sensors |

| Dual-Stage Vent | Porous PTFE membrane | Provides pressure equalization under normal operation and bursts safely under extreme pressure | EV batteries, Battery Energy Storage Systems (BESS) enclosures, mission-critical electronics |

How to Design a Vent for an Enclosure

Creating a properly vented enclosure requires understanding the system’s environmental dynamics, material properties, and performance limits.

Below is a simplified approach to designing a dual-stage vent that balances pressure equalization and burst protection.

Steps for Dual Stage Vent Design (for good pressure equalization and appropriate burst):

1. Determine Venting Requirements

Define key design factors like temperature changes over time for normal venting operation, enclosure size, and maximum pressure.

Example: You have a 10-liter enclosure that will normally see a 27 °C temperature change over an hour, and your enclosure can withstand .5 kPa pressure. Y

Use the airflow equation:

Airflow (L/hr) = Volume × (ΔT / 273 °C)

→ 10 L × (27 / 273) = 1 L/hr airflow needed

2. Select the Right Material

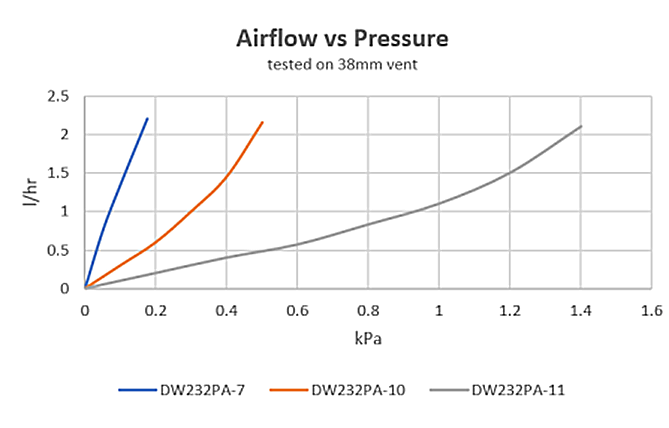

Use the graph below to determine which venting material best fits your needs. Higher airflow enables better equalization.

For the example above, a 10 mil material allows 1 liter/hour airflow without exceeding the 0.5 kPa maximum pressure.

3. Predict Burst Performance

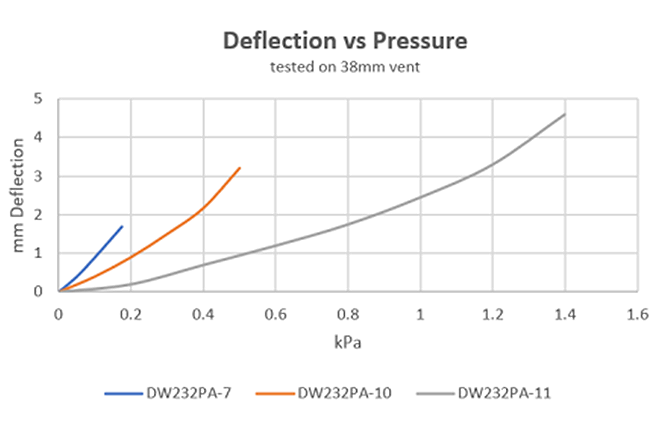

Now use the graph below to find the deflection of your chosen vent material from Step 1, at your enclosure designed maximum pressure to predict your burst pin placement.

The 10 mil material will deflect by 3 mm (in a 38mm diameter vent). The burst pin should be placed closer than 3 mm to the membrane.

4. Test Your Design

Test the vent performance in real-world conditions to ensure proper functionality.

Additional Venting Considerations Beyond Airflow and Water Entry Pressure (WEP)

Beyond airflow and burst pressure, there are several secondary properties that can impact vent reliability:

- Backing - Adding a backer aids in assembly by adding structure to the membrane for improved handling and enables standard adhesives to be used. For example, DeWAL DW373TS is an unbacked ePTFE venting film. DeWAL DW936V material has a polyethylene backer for added stiffness and easier adhesive application, and DeWAL DW932 products have a PET backer for improved mechanical support.

- Temperature - If adding a backer, choose materials that match your temperature requirements: Polyethylene backer: up to 120 °C. PET backer: up to 160 °C.

- Oleophobicity - All ePTFE membranes will allow air to pass in and out of an enclosure to equalize pressure. In addition, they will all keep water from flowing into the enclosure (up to the WEP pressure) and allow moisture vapor to leave the enclosure.

| DeWAL Product | Substrate | Max Operating Temperature | Airflow 1 | WEP 1 |

|---|---|---|---|---|

| °C (°F) | L/Hr/cm^2 @ 70 mBar | kPa | ||

| DW353V-03 | Expanded PTFE | 260 (500) | 20 | 138 |

| DW373TS | Expanded PTFE | 260 (500) | 100 | 62 (minimum) |

| DW932V-12 | ePTFE/Non-Woven PET | 160 (320) | 100 | 276 |

| DW936V-06 | ePTFE/Porous UHMW-PE | 120 (248) | 120 | 207 |

| DW936V-07 | ePTFE/Porous UHMW-PE | 120 (248) | 20 | 345 |

1 Typical values shown are from testing at DOM and should not be used for specification limits.

Key Points

Venting is not just a component choice, it’s an engineering decision that defines the long-term reliability of your enclosure.

By partnering with Rogers and Marian, you gain access to:

- Proven DeWAL venting materials engineered for airflow control and contaminant resistance.

- Expertise in precision converting, ensuring vents integrate cleanly into your enclosure design.

Together, we help ensure your enclosures function reliably in the toughest environments where pressure, moisture, and protection must stay in perfect balance.

Master Enclosure Sealing with the Marian and Rogers Enclosure Institute

Sealing challenges can make or break an enclosure’s performance. Whether you're designing for environmental protection, long-term reliability, or compliance with industry standards, selecting the right materials and understanding effective sealing strategies are critical. That’s why Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute—a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

Why Sign Up for The Enclosure Institute?

Gain exclusive access to:

- Four expert-led modules with in-depth videos, allowing you to learn at your own pace

- Checklists, resources, and tools to guide your enclosure design process

- Actionable insights into real-world sealing challenges

- Certification and an exclusive swag box upon completion, recognizing your expertise

The Enclosure Institute is designed for engineers at all levels, whether you're new to enclosure sealing or looking to refine your expertise.

Enroll today to take the next step in mastering enclosure design.

If you have a specific enclosure challenge and need expert guidance, Marian’s team is ready to help. Contact Marian directly for tailored recommendations and support.

Not ready to enroll yet? Explore more blogs on enclosure design best practices:

- How To Validate Enclosure Seal Reliability Through 5 Tests

- Top 8 Sealing Material Options: How to Choose the Right One for Your Enclosure

- Top 8 Best Practices You Need To Know for Enclosure Die-Cut Gaskets

Your Trusted Partner in Sealing

With nearly 200 years of material expertise, 70 years of fabrication development, decades of partnership, and thousands of applications designed together, Marian and Rogers bring unmatched knowledge to enclosure sealing. By combining Rogers’ high-performance materials with Marian’s precision converting capabilities, we deliver custom-engineered solutions that enhance durability, reliability, and performance.

Whether you need expert guidance, high-quality materials, or precision-fabricated components, our partnership ensures your enclosures meet the highest industry standards while optimizing efficiency and cost-effectiveness.

Published on Oct 16, 2025

Institute Insight

Institute Insight