Published

by Rogers Corporation

Elastomeric Material Solutions

An important design factor for engineers to consider is the temperature at which the material will be exposed throughout the product's life. Elastomeric materials will respond differently to changes in temperature depending on the material chemistry, so it is critical to understand how a specific material will perform in the application.

Let's dive into general temperature guidelines and which temperature values you should look for during material selection.

Why is Temperature Important During Elastomeric Material Selection?

Temperature is critical because it directly impacts both a material's properties and longevity, which can ultimately affect your product and application success.

Selecting a material with the appropriate temperature resistance rating for your operating conditions will enable safety, reliability, and optimal design performance.

What Are the Two Types of Temperature Values You Should Consider in Your Application Design?

The two types of temperature values you should consider in your application design are:

1. Minimum and Maximum Operating Temperature (Continuous Temperature)

Why It Matters

Maximum and minimum operating temperatures (continuous temperature) are particularly important if you are designing a product for use in a wide range of temperatures, such as in the desert or the Arctic. You will need to make the right choice, so the material and your product survive. Materials like silicone or PTFE may be ideal for extreme temperatures due to their high thermal resistance.

Maximum and minimum temperature ranges define the environmental limits within which the material can function effectively and safely. Selecting a material with a wide operating temperature range can help ensure your design's durability and reliability across various environmental conditions.

This ensures that the material will perform reliably and safely over its intended lifespan under constant operating conditions. Considering the continuous use temperature range helps you choose a suitable material that maintains its properties, avoids premature failure, and meets regulatory requirements, which ultimately leads to efficient and cost-effective design and operation.

2. Short-Term or Intermittent Exposure Temperature

General Temperature Ranges for Silicone, Polyurethane, UHMW, and PTFE

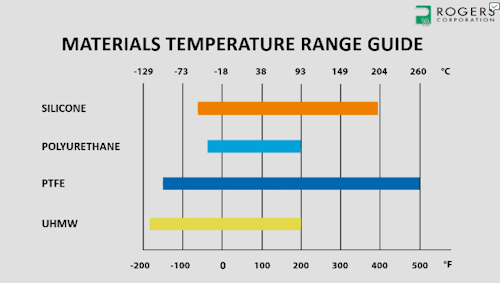

Now that we've reviewed the different temperature values you should consider in your application design, let's look at four common materials engineers use: silicone, polyurethane, UHMW, and PTFE.

Here is an overview of their general temperature ranges. Please note that this is just a general guideline. Actual temperature ranges for specific material will vary.

If you are interested in learning more about the temperature ranges of these specific materials, check out this blog.

Key Points

- Temperature significantly impacts a material's properties and longevity, affecting product safety, reliability, and performance.

- Selecting materials with appropriate temperature resistance is crucial for optimal design and application success.

- The two key temperature values include:

- Minimum and Maximum Operating Temperatures (Continuous Temperature) – The temperature limits within which a material can function effectively without degradation.

- Short-Term or Intermittent Exposure Temperature – Ability to handle brief periods of extreme temperatures to prevent material failure.

- Need help with material selection? Contact a Rogers Sales Engineer to discuss your temperature needs.

Related Content

- Simplify Your Material Search with the New Rogers Material Navigator Tool

- The Ultimate Guide to Compression Force Deflection + Free Tool

- Everything You Need to Know About Compression Set for Elastomeric Foam Materials

Published on Mar 19, 2025