TC350 materials offer designers a unique combination of low insertion loss and higher thermal conductivity. This enables superior reliability and reduced operating temperatures in high power applications.

Features

- Dielectric constant (Dk) of 3.5

- High thermal conductivity of 0.72 W/m-K

- Low thermal coefficient of Dk at-9 ppm/°C, -40°C to 140°C

- Low loss tangent of .002 at 10GHz

- Low coefficient of thermal expansion on X, Y and Z axis (7, 7, and 23ppm/°C respectively)

Benefits

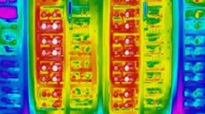

- Reduced junction temperature and improved reliability

- Excellent heat dissipation and management

- Improved bandwidth utilization and efficiency for amplifiers and antennas

- Unsurpassed plated through hole reliability

Please see below for a sampling of data for this material formulation. For detailed material information and to use advanced features such as filtering, visit the Laminate Properties Tool.

| TC350™ | |

|---|---|

| Dielectric Constant, @10GHZ (2.5 GHz) Typical (Process) | 3.50+/-0.05 |

| Dielectric Constant, @10GHZ (2.5 GHz) Typical (Design) | 3.50 |

| Dissipation Factor TAN @10 GHz (2.5 GHz) (Typical) | 0.0020 |

| Thermal Coefficient εr -50°C to 150°C ppm/°C (Typical) | -9 |

| Volume Resistivity Mohm (Typical) | 7.4x106 |

| Surface Resistivity Mohm (Typical) | 3.2x107 |

| Water Absorption D48/50% (Typical) | 0.05(22) |

| Thermal Conductivity W/m/°K (Typical) 50°C ASTM D5470 | 0.72, 1.00(27) |

| Coefficient of Thermal Expansion -55° to 288°C ppm/°C (Typical) X | 7 |

| Coefficient of Thermal Expansion -55° to 288°C ppm/°C (Typical) Y | 7 |

| Coefficient of Thermal Expansion -55° to 288°C ppm/°C (Typical) Z | 23 |

| Peel Strength 1 oz (35um) ED Foil lbs/in. (N/mm) (Typical) | 7.0(1.2) |

| Density gm/cm3 (Typical) | 2.3 |

| Flammability Rating UL94 | V-0 |

| Lead-Free Process Compatible | Y |

| PIM dBc Typical |

Downloads

Applications

View current applications of this product.