Published

by Rogers Corporation

Elastomeric Material Solutions

Two Measures That Out-Perform Thermal Conductivity in Predicting TIM “Real-World” Performance: Exploring Thermal Resistance & Impedance

In our first blog in this series, we explored thermal conductivity and its measurement techniques and explained why your thermal interface material may not be as conductive as you think if you are relying on vendor data sheets. In this blog, we’ll take a closer look at two other measures used in evaluating thermal interface materials (TIM). We will examine thermal resistance and thermal impedance and why both measures can sometimes be more useful measures for designers than thermal conductivity.

The Pros and Cons of Thermal Conductivity Data

Although thermal conductivity is the most recognized and referenced thermal property of a TIM material, it is essentially an idealized value. It’s a great place to start the TIM evaluation process as it describes the ability of a material to conduct heat. This property, however, does not take into account the material size, shape or orientation of a material. It is essentially an idealized value, because it basically gives compares performance given that all geometry and interfacial effects of the TIMs were equal. As discussed in our previous blog, thermal conductivity doesn’t change with the size or shape of the material. In real life, of course, all materials aren’t equal in size, shape or orientation, so thermal conductivity ignores information that may be vital to a specific application.

Why Thermal Resistance & Thermal Impedance May Help You More

Thermal resistance and thermal impedance can provide designers with more information than thermal conductivity because both measures reflect the geometry (thickness and area) of the assembly. In addition, they include the material interaction with a surface (interface resistance). Therefore, thermal resistance/impedance are more important and practical characteristics than thermal conductivity as they more accurately reflect heat-dissipating capability.

Let’s look first at thermal resistance which is the measure of how a material of a specific thickness resists the flow of heat. As TIM thickness is directly related to the resistance, thinner TIMs transfer heat more efficiently than thicker ones.

The thermal impedance of a material is the sum of its thermal resistance and all contact resistances specific to the interfaces where a TIM meets the heat-generating component and the heat sink. In the real world, components are never perfectly flat or smooth, and surface irregularities create micro-air voids when in contact with the interface material, reducing the effectiveness to transfer the heat.

When a material’s thermal impedance is lower, the material is a better thermal conductor in that specific application. Factors like surface roughness or flatness, clamping pressure, adhesive, surface variations and material thickness all have large impacts on a material’s thermal impedance. This is why thermal impedance is a better “real world” thermal property that conductivity or resistance.

How This Works in Real Life

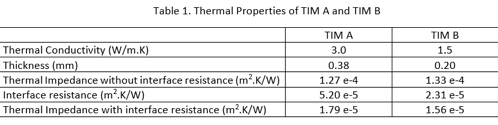

The following example illustrates the challenges a designer faces when selecting a TIM material. Suppose that two thermal interface materials (TIM A and TIM B) are being considered for an application, and let’s look at the test results in Table 1 below:

It is immediately clear that TIM A has a higher thermal conductivity than the alternative. If we only consider thermal conductivity as the critical selection criteria, we will choose TIM A over TIM B every time.

What the designer may be missing, however, is that TIM A is thicker and more rigid, while TIM B is less thermally conductive, but thinner and softer. The thinness of TIM B shortens the distance heat has to transfer within the material and decreases the resistance. In addition, the fact that TIM B is softer means that it can wet out the substrate better, entrapping less air, which leads to less interface resistance. The bottom line is that TIM B imposes less thermal impedance over heat transfer and is more quick and efficient to transfer heat than TIM A.

Why is Using the Right Measure So Important?

In our real-life case, you can see that thermal resistance and thermal impedance can provide designers with more information than thermal conductivity, and that thermal impedance, in particular, can be extremely useful in evaluating the efficiency of a TIM material. For your design, that means greater safety as the more effective the TIM, the better it can be at preventing overheating and malfunctions, reducing downtime and increasing service life of devices. The end result is better energy efficiency, lower manufacturing costs, and lower maintenance cycles and costs.

So the next time you are evaluating TIM materials for your application, you can start with thermal conductivity for general comparisons, but you will find that thermal resistance and impedance data will likely be better measures for your “real world” condition.

Our Next Topic

In the next blog in our Designing for Thermal Management series, we will address how bonding strength can be critical to thermal management design. We hope you will subscribe to Rogers Corporation’s blog to make sure you don’t miss future topics of interest.

To learn more about ARLON Secure Silicone Thermal Transfer Adhesives, visit our website.

Related Products:

Arlon Silicones

Tags:

General Industrial, Thermal Management

Published on Jul 10, 2019