Published

by Stefan Lutter – Manager Product Management, AES

Advanced Electronics Solutions

About two decades ago, engineers in the field of laser technique were looking for a partner to design and build high power coldplates that could support their need for a cutting-edge cooling system targeted to their laser bars. Together with the curamik® engineering team the idea of bonded micro-channel-coolers was born. Since then, high-end liquid cooling systems have become more applicable in an abundance of diverse markets today. If you are looking for more information or would like to talk about your application, please get in touch with us or stay tuned for deeper insights into our MCC market series launching next year.

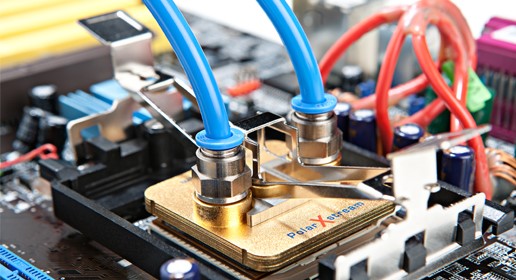

High Performance Computing

LED Array Cooling

Due to their increasing light output, high-performance LEDs are becoming commonplace for new applications in medical technology, industrial image processing and UV curing of adhesives. In order to expose large-area objects hundreds of power LED chips must be brought together in a very small space. As a result, thermal problems can arise more often. In addition, especially in the UV range, high demands are placed on the constancy of optical parameters, such as wavelength, chromaticity coordinates, forward voltage and light output. Temporary temperature changes or even a strong inhomogeneous temperature distribution across the power module are unacceptable. Nonetheless, Rogers offers optimized and customized coolers to meet your specific needs.

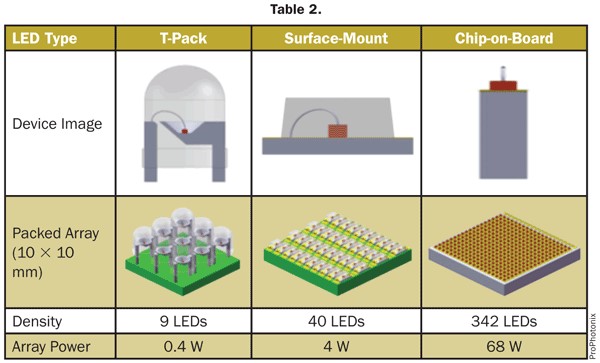

LED Type packaging density

Source: Photonics Media (2020), “LED-Based Sun-Simulator Design: Technical and Commercial Considerations”, retrieved from: https://www.photonics.com/Articles/LED-Based_Sun-Simulator_Design_Technical_and/a57253

Concentrated Photovoltaics (CPV)

Unlike conventional photovoltaic systems, lenses and curved mirrors are used to focus sunlight onto small but highly efficient multi-junction solar cells (MJ). CPV systems often use solar tracking systems and on occasion are coupled with a cooling system to further increase efficiency. Systems with highly concentrated photovoltaics (HCPV) are entering a competitive space. They are the most efficient among all existing PV technologies and with a smaller photovoltaic system they are capable of reducing overall system costs. Currently, CPV is not used in the rooftop PV segment and is far less common than conventional PV systems. Modern CPV systems work most efficiently in highly concentrated sunlight (i.e. concentrations equivalent to hundreds of suns), if the solar cell is kept cool by using heat sinks. In this scenario, Rogers Corporation can support your application with bare copper or insolated micro-channel heat sinks.

CPV Triple Junction Solar Cell Module – Type 3C30M

Source: AZUR SPACE Solar Power GmbH (2020), “CPV Dense Array Module”, retrieved from: http://www.azurspace.com/index.php/en/products/products-cpv/cpv-dense-array-module

High Power Laser Market

Do you have any question or require some information about our coolers? Please contact us, if you need assistance.

Related Products:

curamik Cooling Solutions

Tags:

Olivier's Twist Blog, General Industrial, Wired Infrastructure

Published on Dec 03, 2020