Published

by Rogers Corporation

Elastomeric Material Solutions

Selecting the right materials can be a challenge, especially when faced with a whole lot of complex technical terminology. Making informed design choices requires a clear understanding of a material’s unique properties and what makes it ideal for real-world applications.

Rogers, a leader in high-performance materials, offers a wide range of DeWAL® specially- manufactured PTFE and UHMW-PE solutions designed to meet the needs of demanding applications.

To help you better understand these innovative products and make more informed material design choices, we’ve outlined the essential terms you should know when working with PTFE and UHMW-PE tapes and films.

Understanding the Core Chemistries

Before diving into the world of these materials, let’s start with a high-level review of the chemistries that are used to manufacture DeWAL products.

DeWAL products focus on two main material chemistries, PTFE and UHMW-PE.

PTFE (Polytetrafluoroethylene)

Definition:

PTFE is a high-performance polymer with excellent thermal stability, chemical inertness, and a low coefficient of friction. These properties make it a go-to material for industrial and mission-critical applications. PTFE can sometimes be referred to by one of its brand names, Teflon®.

*Teflon is a trademark of Chemours™

Applications:

- Heat sealing

- Insulation

- Machinery components

- Industrial linings

- Aerospace

- Electrical insulation

- Food processing

UHMW-PE (Ultra-High Molecular Weight Polyethylene)

Definition:

UHMW-PE is a highly durable polymer known for impact resistance, low friction, and incredible abrasion resistance. Its toughness and longevity make it a good choice for heavy-duty industrial applications.

Applications:

- Conveyor belts

- Liners

- Protective coatings

Material Forms and How They’re Made

The end products made from these materials can take many different forms depending on the performance goals of the application. The method by which the materials are produced impacts their flexibility, durability, physical properties, and how they are referred to in the industries in which they are used.

Rogers DeWAL PTFE and UHMW-PE products come in one of two primary formats depending on how they’re manufactured.

Sintered Versus Unsintered Materials

Sintering is the process of heating resin in its raw material form to eliminate the grain boundaries, which changes the form factor of the materials.

Great…but what does that mean?

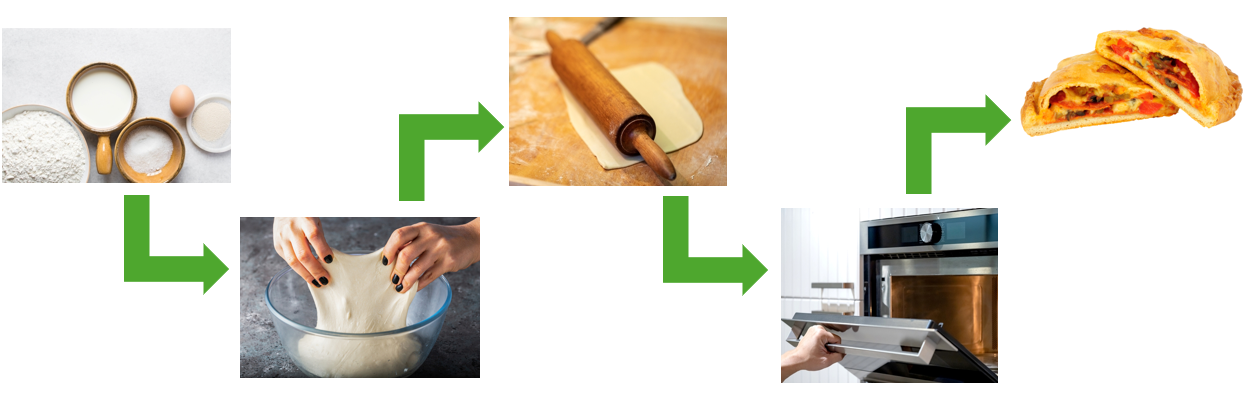

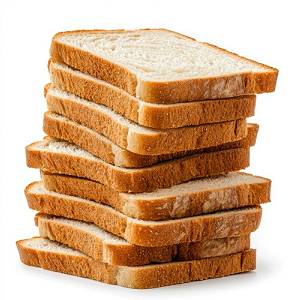

You can think of this as baking bread.

Sintered

How to think about it: When you make bread, you begin with an ingredient list. The list usually includes flour, yeast, sugar, salt, and liquid (but we’ll talk about liquids later).

The dry ingredients of the recipe are similar to PTFE resin; we can press them together and with enough time and pressure they will combine as one, but the mixture is unstable until it is baked. This is where the liquid comes in.

How to remember it: Baking bread is similar to the sintering process as the various components blend together to form a solid.

Where it is used: Applications in which a strong barrier is needed, such as electrical insulation applications.

Makes sense right—but what about unsintered?

Unsintered

How to think about it: Let’s go back to the baking bread analogy and add liquid to the dry components. Once the liquid is added, you’ve formed the dough. The dough is semi-stable but very malleable; it can be stretched and manipulated into different shapes, thicknesses, etc.

In this case, the dough is what unsintered PTFE is like. Although it is held together, the form is not fully stabilized. Stabilization of the form occurs when the dough is made into different products, such as wrapping it around other ingredients to make a calzone and baking it to become dimensionally stable.

How to remember it: Think of unsintered PTFE as dough before it is baked and turned into bread.

Where it is used: Wire and cable wrapping applications where flexible material is required that can be heated to retain its shape.

PTFE resin is like the dry ingredients for bread, which are pressed together to combine as one.

Unsintered PTFE is not in its final form and is not fully stabilized, like dough before it is baked.

The sintering status of a material directly impacts how it handles. For this reason, sintered and unsintered materials are often referred to differently in their final format.

Skived vs. Extruded

Let's talk more about bread.

Skived

How to think about it: Remember that when we hold the ingredients together with enough time and pressure and then bake, we get a solid loaf of bread. But to eat the bread, we usually slice it before using it to make something else. Slicing the bread is basically what happens with a skived film. A skived film is sliced from a solid cylinder of PTFE or UHMW-PE, creating thin, smooth layers with precise thickness… similar to a slice of bread.

How to remember it: Skiving = slicing a finished loaf of bread.

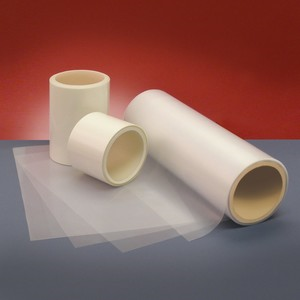

What we call it: Skived films are thin sheets or tapes sliced from a solid PTFE cylinder. Skived PTFE and UHMW-PE materials are often referred to as films. These film materials offer the benefit of extremely thin profile offerings with very precise thickness tolerances and smooth surfaces.

Where it is used: Ideal for gaskets or electrical insulation applications where thin, flexible layers are required.

Extruded

How to think about it: Extrusion, on the other hand, is like rolling out dough. Extruding film does not use a sintering process until after the film has been made. In many cases it will not be sintered until it is turned into a finished product (remember that calzone?). In extrusion we are only working with the dough. We use the liquid to reach the right consistency and force the dough through an extrusion process and use a roller to get it to the right thickness. From here the material gets rolled up and shipped to the baker.

How to remember it: Extrusion = rolling out dough.

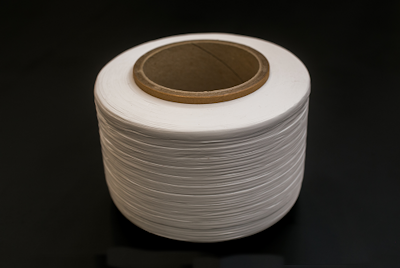

What we call it: Extruded films are manufactured by forcing the material through a die, yielding consistent shapes and lengths. In the context of DeWAL materials, these are often unsintered thin PTFE-based materials referred to as “tapes” in the industry. However, extruded material can take many different shapes and forms.

Where it is used: Ideal for tubing or liner applications where durability and uniformity are required.

Thin sheets of PTFE are skived from a solid cylinder, like slicing bread from a loaf.

To recap:

| Sintered | Unsintered | Skived | Extruded |

|---|---|---|---|

|

|

|

|

| Example: DeWAL 2000 | Example: DeWAL 203 | Example: DeWAL 212 | Example: DeWAL 330 |

Applications:

|

Applications:

|

Applications:

|

Applications:

|

#StickwithDeWAL

Whether you're looking for temperature-resistant PTFE, durable UHMW-PE, or a specific type of adhesive backing, having a good grasp of the basic terminology will help you make the best material choice for your unique needs. Find more information about DeWAL products.

For more information on the DeWAL product line, reach out to a Rogers Sales Engineer.

In Part 2, we’ll explore how DeWAL materials can be further enhanced through techniques like expansion, conductive layering, and adhesive integration to meet more specialized application requirements.

Related Blogs

- Simplify Your Material Search with the New Rogers Material Navigator Tool

- New DeWAL® Tool Improves Search and Offers Advanced Features

- Top 5 Things You Might Not Know About PTFE Tapes

Related Products:

DeWAL Products

Published on Jul 09, 2025