Published

by Rogers Corporation

Elastomeric Material Solutions

When you're designing for electrically sensitive or safety-critical applications, understanding how materials behave under flame exposure is essential. UL 94 flame ratings are a widely recognized benchmark for evaluating polymer and foam performance, but navigating the various tests, classifications, and certification data can be challenging. To help clarify what engineers need to know, we turned to the one and only Dan Kubick, Principal Service and Development Engineer at Rogers Corporation.

With over 39 years in the silicone industry, Dan has supported countless engineers in selecting materials that meet both performance and compliance demands. Among the many questions he fields, one continues to stand out:

“Does Rogers Corporation have UL recognition for its materials?”

The short answer is yes — but as any engineer knows, what really matters is understanding how those materials perform, which tests they’ve passed, and what that means for your design.

This blog explores the essentials of UL 94: what the standard covers, which Rogers materials are recognized, and how to find and interpret listings on the UL website. Whether you're designing for electronics, appliances, medical devices, or transportation, understanding fire safety is critical.

What Is UL 94?

UL 94 is a flame rating standard developed by Underwriters Laboratories (UL) to classify the flammability of plastic and polymeric materials. While originally created for rigid plastics, it’s now widely used across elastomers, cellular foams, and sponges, including many of the materials used in gasketing and sealing applications.

UL 94 testing helps engineers evaluate a material’s ignition behavior, burning rate, and self-extinguishing performance — all critical factors in applications where fire safety and reliability matter.

Common Applications That Require UL 94 Ratings:

- Electronic enclosures and electrical equipment

- Automotive interiors and components

- Aerospace applications

- Medical devices and appliances

UL recognition builds confidence in material choice and supports compliance with industry safety requirements.

Now let’s dive into the actual tests within the UL 94 standard.

Flame Test Methods in UL 94

UL 94 includes six test configurations, each designed to measure flammability in different conditions. Each has its own set of criteria for passing or failure of the test.

The three most commonly requested tests in gasket fabrication and elastomer design are: Vertical (V-0), Horizontal (HB), and Horizontal (HBF) burning performance.

| UL Flame Rating | ASTM Test Method | Description |

|---|---|---|

| Horizontal Burning Test (HB, HBF) | ASTM D635 | Test method for rate of burning of self-supporting plastics in a horizontal position. |

| 50W (20mm) Vertical Burning Test | ASTM D3801 | Test method for the comparative burning of solid products in a vertical position. |

| 500W (125mm) Vertical Burning Test | ASTM D5048 | Test method for measuring the comparative burning characteristics and resistance to burn through of solid plastics using a 125mm flame. |

| Radiant Panel Flame Spread Test | ASTM E162 | Test method for surface flammability of materials using radiant heat energy source. |

| Thin Material Vertical Burning Test | ASTM D4804 | Test method for determining the flammability characteristics of nonrigid solid plastics |

| Horizontal Burning Foamed Material Test | STM D4986 | Test method for horizontal burning characteristics of cellular polymeric materials. |

The most requested standard for most industries is the UL94 V-0 50-watt recognition for a material. This shows the capability of a material to extinguish and not spread any flame in the event of a fire event.

Rogers Materials with UL 94 Recognition

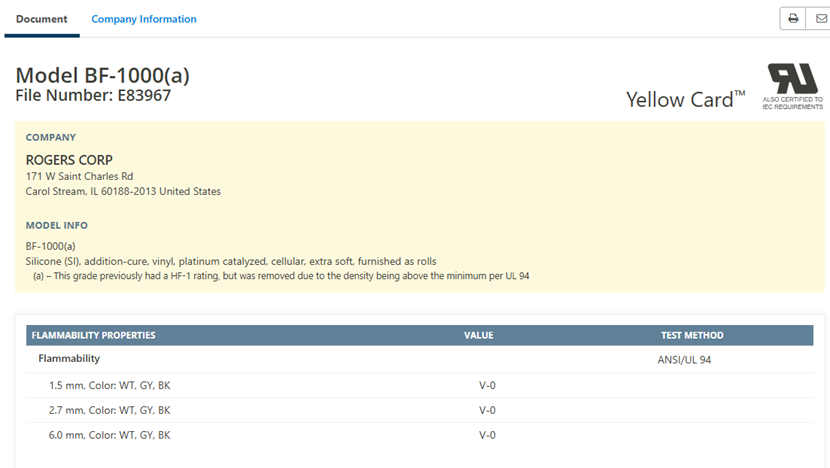

Several BISCO® silicone products from Rogers Corporation are listed under UL 94 with V-0 or HF-1 ratings. These materials are tested at specific minimum thicknesses and color variants, which can affect their flame behavior.

| BISCO Silicone Product | Colors | Minimum Thickness | Rating |

|---|---|---|---|

| BF-2000 | Black | 2.2mm | V-0 |

| BF-2000 | Black | 2.6mm | HF-1 |

| BF-1000 | White, Black, Gray | 1.5mm | V-0 |

| HT-870 | Black, Red | 1.5mm | V-0 |

| HT-870 | Black, Red | 1.5mm | HF-1 |

| HT-800 | Black, Gray | 0.7mm | V-0 |

| HT-800 | Red | 3.0mm | V-0 |

| HT-820 | Gray | 0.7mm | V-0 |

| HT-840 | Gray | 1.6mm | V-0 |

| HT-6360 | Black | 0.5mm | V-0 |

How to Find UL 94 Certified Rogers Materials on UL.com

To confirm whether a Rogers material is UL 94 certified — such as BISCO® silicones, PORON® polyurethanes, or ARLON® silicones — follow these simple steps:

- Step 1: Go to UL’s Product iQ database at UL.com. This is UL’s official certification search tool.

- Step 2: Click on “Search Certifications” or go directly to “Find a Product Certification”.

- Step 3: If prompted, create a free UL Product iQ account. You’ll need to sign up with a unique password to view full certification details.

- Step 4: In the search bar, type “Rogers Corp”. This will return listings for Rogers Corporation materials across multiple product families.

- Step 5: Filter or scroll to find the material family you’re looking for — such as:

- BISCO® silicone foams

- PORON® polyurethane foams

- ARLON® silicone materials

- Step 6: Review the certification details. Make sure to check the flame rating (e.g., UL 94 V-0), minimum thickness, and approved colors. Only products listed on UL.com carry official UL recognition.

What Happened to the Yellow Card?

Engineers sometimes ask, “Do you have a yellow card on this product?”

Years ago, UL provided certified material info on physical yellow postcards. In the digital age, this data is now available online. After locating your product on UL.com, you can click a link to download the electronic Yellow Card, which includes flame ratings and certified test conditions.

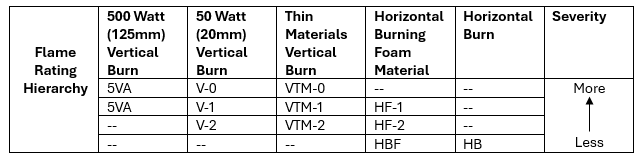

Flame Rating Hierarchy

UL 94 flame ratings evaluate flammability characteristics based on how the material burns when exposed to a flame, including ignition resistance, flame propagation, dripping, and self-extinguishing behavior.

Flame ratings are broken into several classifications, including both horizontal and vertical test configurations.

Each of the five test types below carries a different level of severity, which should be carefully matched to your application’s requirements. A design engineer will typically determine what’s needed based on internal standards or by working with an underwriter’s project manager.

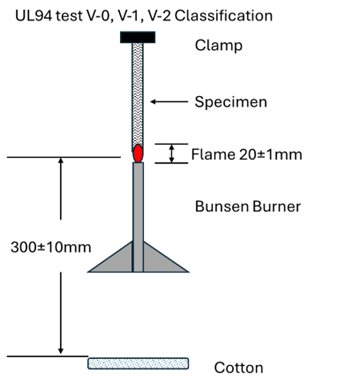

50 Watt Vertical Burn Test (UL 94 V-0, V-1, V-2)

The 50 Watt (20mm) vertical burn is the most widely referenced test in the UL 94 standard and is often used as a baseline requirement in flame-critical applications.

This test evaluates a material’s ability to self-extinguish and resist flame spread in a vertical orientation — a more severe scenario than horizontal tests.

The test involves a standard specimen of 125 ±5 mm by 13 ±0.5 mm, tested in both a minimum and maximum thickness (not to exceed 13 mm). While thickness and color are included in the final recognition, density is not reported but is known by the manufacturer.

Two sets of samples are prepared:

- As-received: preconditioned for 48 hours at 23°C and 50% humidity

- Heat-aged: conditioned for 168 hours at 70°C, then cooled to room temperature

Each sample is exposed to a Bunsen burner flame (20 ±1 mm) for 10 seconds. A piece of cotton is placed below the specimen to detect flaming drips. The flame is removed, the extinguishing time is recorded, then the process is repeated for the second sample.

If any sample fails, a second set of specimens is used for confirmation.

UL 94 Vertical Burn Criteria

| Criteria Conditions | V-0 | V-1 | V-2 |

|---|---|---|---|

| Afterflame time for each individual specimen t1 or t2 | ≤10s | ≤30s | ≤30s |

| Total Afterflame time for any condition set (t1 plus t2 for the 5-specimen set) | ≤50s | ≤250s | ≤250s |

| Afterflame plus afterglow time for each individual specimen after the second flam application (t2+t3) | ≤30s | ≤60s | ≤60s |

| Afterflame or afterglow of any sample up to the holding clamp | No | No | No |

| Cotton indicator ignited by flaming particles or drops | No | No | No |

Horizontal Burn Foam Test (HBF)

The Horizontal Burn Foam (HBF) test is used to evaluate non-structural foam components in devices and appliances.

Historically, UL defined HBF testing as applying only to low-density foam materials. However, in early 2023, UL redefined “low-density” to include only materials with a density below 250 kg/m³. As a result, many previously recognized materials lost their HBF listings.

That doesn’t mean the materials are no longer usable — it just means they may now be tested to the HB classification instead. If you’re unsure which applies, consult the UL listing or work with a Rogers technical expert.

The test uses a specimen measuring 150 ±5 mm by 50 ±1 mm, tested in both minimum and maximum thicknesses (up to 13.0 mm). While color and thickness are included in the final recognition, density is not reported, but is known by the manufacturer.

Two sets of samples are prepared:

- As-received: preconditioned for 48 hours at 23°C and 50% humidity

- Heat-aged: conditioned for 168 hours at 70°C, then cooled to room temperature

A Bunsen burner with a wing tip is placed under the edge of the foam specimen to ignite it horizontally. A piece of cotton is placed below to detect flaming drips. The application time is 60 seconds, and the time it takes for the flame to travel from the 25 mm to 125 mm mark is recorded.

The results of both as-is and conditioned samples are checked against the chart below. If there is a failure of a single sample, then a second set of specimens are used for a confirmation of the testing.

UL 94 HBF Classification Criteria

| Criteria Conditions | HF-1 | HF-2 |

|---|---|---|

| Afterflame time, t1 | 4/5 is ≤2s 1/5 is ≤10s |

4/5 is ≤2s 1/5 is ≤10s |

| Afterflame time plus afterglow time for each individual specimen, t1 + t2 | ≤30s | ≤30s |

| Cotton indicator ignited by flaming particles or drop | No | Yes |

| Damage length for each individual specimen | <60mm | <60mm |

HBF Classification Criteria

A material is classified as HBF if it meets either of the following conditions:

- The burning rate does not exceed 40 mm per minute over a 100 mm span, or

- Each specimen ceases to burn before reaching the 125 mm gauge mark, without flaming or glowing.

Final Tips: Ensuring Your Material Carries True UL Recognition

Before specifying a material based on UL 94 flame performance, keep the following in mind to avoid delays, surprises, or compliance issues:

- Verify official UL recognition

Always check UL.com using the “Find a Product Certification” tool. You’ll need to sign up for access. Only materials listed on UL’s site are considered officially recognized. - Beware of third-party claims

Some suppliers may claim their materials meet UL 94 without undergoing formal UL certification. Even if tested in third-party labs, results are not valid unless conducted by UL itself. - Know the minimum rated thickness

Flame performance varies with thickness — many materials are only certified at thicker dimensions. Thinner versions may not meet the same rating. - Check approved colors

Flame behavior is color-dependent. A material might pass UL 94 in one color but fail in another. Red, for example, tends to perform worse in flame tests and must be listed specifically.

Key Takeaways

- UL 94 is a critical flame rating standard for plastics, elastomers, and foams used in electrical and safety-critical applications.

- Rogers BISCO® silicones meet stringent UL 94 ratings, including V-0 and HF-1, at specific thicknesses and colors.

- The 50W vertical burn test (UL 94 V-0) is the most common requirement. Rogers materials have been tested to this standard.

- The HBF test has changed due to UL’s revised “low-density” definition; check if your material still qualifies.

- Always verify UL listings on UL.com — only listed materials carry official UL recognition.

- Watch out for minimum thicknesses and approved colors, as they directly impact flame performance and certification validity.

If you need help identifying the right UL 94-certified material for your design, reach out to a Rogers Sales Engineer.

Related Blogs:- How to Ensure Rail Car Safety: Key Standards EN 45545-2 and 49CFR238/ NFPA 130

- How to Choose a Reputable Silicone Supplier: Top 6 Tips

- Beyond the Price Tag: Long-Term Savings with Silicone

Published on Jul 28, 2025