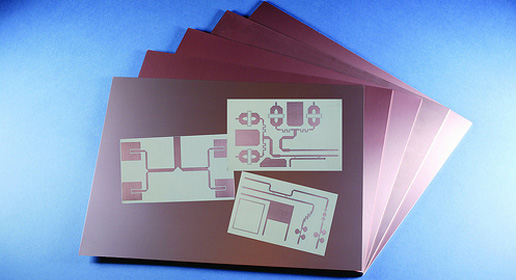

Designed for use as inner-layers in multi-layer board (MLB) designs, RO4835T complements RO4835™ laminates when thinner cores are needed. RO4835T laminates feature high performance material attributes that provide an optimum blend of price, performance and durability with the capability of being fabricated using standard FR-4 (epoxy/glass) processes.

Features

- Dielectric constant (Dk) of 3.3

- Excellent oxidation resistance, compared to typical thermoset microwave materials

- Low loss, low CTE material

- Flame retardant laminate, UL 94 V-0 rated

Benefits

- CAF resistant

- Ease of PCB manufacturing and assembly in line with FR-4

- Minimizes local variation of dielectric constant

- Improved MLB design flexibility

- Improved design flexibility, PTH reliability and automated assembly compatibility

Please see below for a sampling of data for this material formulation. For detailed material information and to use advanced features such as filtering, visit the Laminate Properties Tool.

| RO4835T™ | |

|---|---|

| Dielectric Constant, @10GHZ (2.5 GHz) Typical (Process) | 3.33+/-0.05 |

| Dielectric Constant, @10GHZ (2.5 GHz) Typical (Design) | 3.48 |

| Dissipation Factor TAN @10 GHz (2.5 GHz) (Typical) | 0.0030 |

| Thermal Coefficient εr -50°C to 150°C ppm/°C (Typical) | 35 ppm/C (from -50 to 50C), -35 ppm/C (from 50 to 150C) |

| Volume Resistivity Mohm (Typical) | 1.34x108 |

| Surface Resistivity Mohm (Typical) | 1.17x106 |

| Water Absorption D48/50% (Typical) | 0.20 |

| Thermal Conductivity W/m/°K (Typical) 50°C ASTM D5470 | 0.53, 0.52@80° |

| Coefficient of Thermal Expansion -55° to 288°C ppm/°C (Typical) X | 14 |

| Coefficient of Thermal Expansion -55° to 288°C ppm/°C (Typical) Y | 16 |

| Coefficient of Thermal Expansion -55° to 288°C ppm/°C (Typical) Z | 62 |

| Peel Strength 1 oz (35um) ED Foil lbs/in. (N/mm) (Typical) | 3.0 (0.53) |

| Density gm/cm3 (Typical) | 1.81 |

| Flammability Rating UL94 | V-0 |

| Lead-Free Process Compatible | Y |

| PIM dBc Typical |

Downloads

Applications

View current applications of this product.