Rogers Corporation has over 40 years of experience in power electronics systems, providing exceptional technical expertise to product designers at any stage of production. Our R&D department provides extensive knowledge of the electrical, chemical and mechanical behavior of electronics in high power environments. Our Engineering department fine-tunes designs using state-of-the-art development tools to address temperature load, current density and loop inductance. Our goal is to help designers create the highest quality design within a budget.

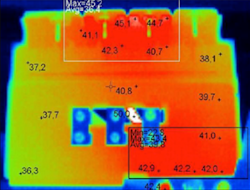

Rogers Co-engineering begins with a detailed analysis of current processes, materials and costs. From there, the right material is chosen: conductors, insulation, plating and inserts. We create a detailed 3D design that become prototypes - created and tested with detailed inspection at each step. To ensure proper material characteristics, products are subjected to peel testing, SAFT testing, cleavage testing and tensile testing. Before final shipment, products are subjected to thorough First Article Inspection (FAI), including high voltage and partial discharge testing, inductance and capacitance testing, 3D measurements and thermal cycling.

Find out about our patented technology that’s at work in our innovative designs: