Published

by Rogers Corporation

Elastomeric Material Solutions

For decades, flammability in automotive design was benchmarked by horizontal burn tests like FMVSS 302.

But today, industries are shifting toward the more stringent UL 94 V-0 vertical burn standard. The change reflects a broader trend: as systems become more compact, powerful, and safety-critical, expectations for flame performance are rising across the automotive, battery energy storage system (BESS), data center, and even rail industries.

We spoke with Chris Churchill, Senior Manager of Technical Service at Rogers to explore why this shift matters and how the new PORON® 40V0 polyurethane foam positions engineers ahead of the curve.

Q&A with Chris Churchill, Technical Service Senior Manager

Q: Chris, how important are flammability standards in automotive design? Why do they matter?

Flammability standards are critical, especially with the growth of EVs. Automakers want to ensure materials can self-extinguish and reduce risk in the event of ignition.

Historically, the industry has relied on FMVSS 302, which is a horizontal burn test. Now we’re seeing industry leaders shift toward UL 94 V-0, a vertical burn test that is far more stringent. That shift raises the bar for safety in areas where electrical and thermal risks are higher.

Q: What is the difference between FMVSS 302 and UL 94 V-0?

FMVSS 302 is a horizontal burn test and is generally easier to pass. A material can continue burning the full sample length and still qualify as long as the burn rate stays under the limit.

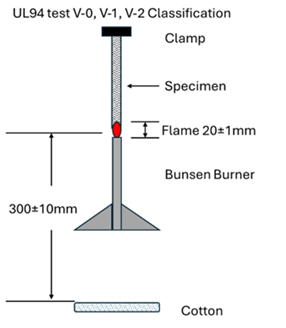

UL 94 V-0, on the other hand, uses a vertical orientation. The material must self-extinguish within 10 seconds, with no flaming drips that ignite cotton and strict limits on afterflame and afterglow. It’s a much tougher measure of how materials behave in real-world conditions.

Read more information on UL94 flame ratings.

Q: How are OEMs responding to these changes?

We’re already seeing momentum in automotive. Many OEMs are updating their internal specifications to reference UL 94 flame ratings, though not always V-0. In some cases, horizontal burn tests such as UL 94 HBF are now being accepted in place of legacy standards.

European OEMs are often already aligned with UL standards. While not universal yet, the direction is clear: engineers are being asked to meet V-0, where previously FMVSS 302 was acceptable.

Q: Beyond automotive, where else are you seeing demand for V-0 materials?

Battery Energy Storage Systems (BESS):

I’m seeing demand in battery energy storage systems (BESS). UL 9540 and 9540A are not material tests, they are system-level evaluations that look at how an entire enclosure performs under thermal runaway and propagation scenarios.

What we see in practice is that customers often work backwards: if their enclosure must pass a 9540A test, they want every component to contribute positively to the performance of the system.

That’s why more designers are defaulting to using UL 94 V-0 materials even when the spec does not explicitly require it. It’s a form of risk management. If the foam gaskets and gap pads are self-extinguishing, that’s one less variable to worry about during system testing. PORON 40V0 foam supports this approach by combining V-0 compliance with softness and compressibility, which makes it easy to design into BESS modules and enclosures where both safety and mechanical reliability matter.

Data centers are another area. Some server OEMs only allow V-0 materials on their approved lists. Historically, silicone materials dominated those spaces. With PORON 40V0 foam, we now have a polyurethane option that delivers the V-0 flame rating while also helping with low-frequency acoustic absorption, which is a real benefit in fan and motor applications.

Rail:

Seating is worth highlighting as well. Applications in rail must meet some of the most stringent flammability and safety standards, such as EN 45545 in Europe. While PORON® 40V0 wasn’t developed specifically for these markets, its UL 94 V-0 rating, soft compressibility, and durability make it a candidate to be tested or evaluated against seating requirements in rail environments.

Q: What does this shift mean for material selection?

Historically, if you needed UL 94 V-0 compliance, the default choice was silicone foam. That’s still the best option when you need extreme temperature stability or outdoor durability, though it often comes at a higher cost.

PORON 40V0 foam gives engineers another option: a softer, more compressible polyurethane that meets UL 94 V-0 down to 3 mm thickness. It’s siloxane-free and halogen-free, and it provides long-term stress relaxation resistance.

For applications like control module seals, NVH pads, gap-filling around electronics, or enclosure gasketing, it delivers the flame rating without over-specifying the material.

Q: What advice would you give engineers navigating these evolving standards?

First, keep an eye on your industry’s specifications. Even if your company’s internal material requirement is FMVSS 302, many OEMs are moving toward UL 94 V-0. It’s wise to start qualifying materials now that align with where standards are heading.

PORON 40V0 polyurethane foam was designed with that transition in mind. By sampling early, you can ensure compliance with tomorrow’s standards while also benefiting from the softness, acoustic absorption, and cost efficiency of polyurethane compared to other options.

Learn More

Flammability standards are evolving, with industry moving from horizontal tests like FMVSS 302 to the more demanding UL 94 V-0. PORON 40V0 foam gives engineers a reliable, cost-effective material choice that meets today’s needs while preparing for tomorrow’s standards.

Request a sample of PORON 40V0 polyurethane foam.

For more information, read this blog on on UL94.

Published on Sep 24, 2025