Published

by Rogers Corporation

Elastomeric Material Solutions

In the early days of electric vehicles, engineers celebrated the quiet cabin until they realized that silence made every squeak, buzz, and rattle impossible to ignore. The same principle applies in data centers, where a low hum from fans and racks can affect both comfort and performance.

As technology gets quieter, the small sounds stand out. That is where PORON® 40V0 polyurethane can help make a difference. It combines fire safety, sealing performance, and low-frequency acoustic & vibration control to help engineers design systems that perform as quietly as they run.

We spoke with Eric Beaudry, Technical Service & Development Engineer at Rogers Corporation, to understand how PORON® 40V0 material performs and where it fits best.

Q&A with Eric Beaudry, Technical Service & Development – Acoustic Management

Q: Why do acoustics and vibration matter across industries?

They impact user comfort, perceived quality, and even safety. Unmanaged vibration can drive fatigue, wear and tear, and potential failure, as famously seen in the collapse of the Tacoma Narrows Bridge, where wind-induced oscillations grew uncontrollably.

In vehicles, mounts and isolators decouple passengers from vibration. In electronics and equipment, similar principles apply.

Anything that can vibrate will, and it needs to be controlled.

Q: Are acoustic demands increasing with EVs and modern electronics?

Yes. Electric vehicles lower the overall noise floor, so sounds that were once masked by engine and road noise, such as buzzes, rattles, or road noise, are now much more noticeable.

In consumer electronics, even a minor rub or buzz near buttons, speakers, or housings can affect perceived quality. Across appliances and home entertainment systems, vibration and noise control have become integral solutions tied to the user experience.

Q: Why do acoustics and vibration matter in data centers?

Data centers consume massive energy and generate a lot of heat, requiring massive cooling solutions including high-powered fans, compressors, and HVAC systems. These components create noise and vibration that travels through floors and racks, potentially disturbing sensitive hardware. Even small-amplitude vibrations can impact hard drive performance and cause read and write errors, making vibration and acoustic management key to system reliability.

Q: What did early testing show for PORON® 40V0 material acoustics?

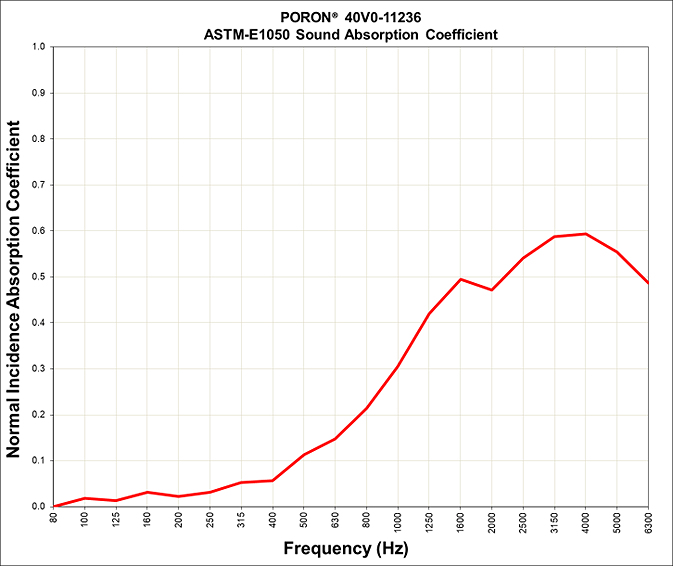

Independent impedance-tube testing showed that PORON 40V0 foam offers modest overall absorption with a relative advantage at lower frequencies compared to other UL94 V-0 options.

As shown in the chart, PORON® 40V0 polyurethane begins to absorb sound energy around 800 Hz and continues to perform effectively through the mid-frequency range, peaking near 0.6 between 3–4 kHz. While it is not intended to be a dedicated acoustic foam, it offers noticeable absorption in the low- to mid-frequency bands where vibration, fan, and motor noise are common.

While it is not designed to replace dedicated acoustic solutions, PORON® 40V0 foam provides useful low-frequency absorption along with its primary strengths: UL 94 V0 compliance, softness, and conformability for sealing and gasketing. It is a strong option when acoustic absorption or vibration isolation and sealing are required, with the added benefit of low-frequency damping.

Where Low-Frequency Benefits Matter Most

Low-frequency noise and vibration are some of the most challenging performance issues to manage due to their long wavelengths. Motors and fans generate low-frequency vibration due to balance and motor pulsing. Fans are problematic due to blade passing tones, which are challenging to absorb. In these cases, vibration isolation and acoustic absorption solutions work best to manage noise and vibration challenges.

Applications that benefit from PORON® 40V0 foam’s low-frequency behavior include:

| Property / Need | PORON® 40V0 Foam | Melamine | BISCO® MF1® | V-0 EPDM / Neoprene |

|---|---|---|---|---|

| UL 94 Rating | V0 (3 mm) | V0 | FST | V0 |

| Softness / Compressibility | Good | Excellent | Excellent | Moderate |

| Sealing / Gasketing | ✔️ | ✖️ | ✖️ | ✔️ |

| Low-Frequency Absorption (<1 kHz) | Good | Limited | Limited | Limited |

| High-Frequency Absorption (> 3 kHz) | Fair | Excellent | Excellent | Limited |

| Compression Set / Stress Relaxation | Excellent | Good | Good | Moderate |

PORON® 40V0 Polyurethane in Acoustic Design

When it comes to acoustic materials, it is important to distinguish between absorption and blocking.

- Open-cell foams absorb airborne sound through internal cell friction and irregular structure

- Closed-cell or skinned foams block sound transmission from migrating through materials

Acoustic sealing or blocking is most effective when it is designed in from the start. This limits acoustic energy from entering a system where it becomes harder to manage. Absorption solutions are often utilized to correct issues discovered during testing when noise/vibration are generated and become part of a system and remain unchecked.

PORON® 40V0 polyurethane material provides a balanced combination of both. It is soft and compressible enough to isolate vibration in components, while its open-cell structure delivers meaningful acoustic absorption at lower frequencies.

| Industry | Acoustic Challenge | Role of PORON® 40V0 Foam |

|---|---|---|

| EVs | Cabin rub, buzz, & squeak as well as road & wind noise | Soft isolation and gap-filling with UL94-V0 safety compliance |

| Data Centers | Motor/fan and rack vibration affecting drives | Vibration isolation and low-frequency damping |

| HVAC / Industrial | Fan and compressor noise | Isolation, sealing, and noise absorption for quieter operation |

| Rail / Aerospace | Structure-borne vibration in large assemblies | Gap-tolerant sealing, low-frequency damping, and flame compliance |

As Eric explains, “If the top priority is pure acoustic absorption above about 3 kHz, MRF-400 melamine foams perform better. But when you need fire safety, sealing, and low-frequency absorption in one material, PORON® 40V0 foam is hard to beat.”

Designing for Fire Safety and Acoustics

Eric’s advice for engineers is straightforward:

“Design for vibration isolation and acoustic management based on flammability requirements at the outset. It is far more effective to apply solutions as part of the design phase, than to fix them later, when trade-offs and compromises often appear elsewhere.”

By combining UL 94 V0 compliance, soft sealing performance, and low-frequency absorption, PORON® 40V0 polyurethane helps engineers simplify their designs while meeting multiple design requirements at once, from comfort and reliability to safety and sound management.

Learn More

PORON® 40V0 polyurethane foam was designed to meet today’s growing performance standards for safety and comfort. Its unique balance of V-0 flammability, softness, and acoustic isolation makes it an ideal material for modern EVs, data centers, HVAC equipment, and beyond.

Request a sample of PORON® 40V0 polyurethane foam

Published on Nov 17, 2025