Published

by Rogers Corporation

Elastomeric Material Solutions

When designers move from automotive-grade FMVSS 302 or UL 94 HB/HBF to UL 94 V0, the goal is more than compliance, it’s about engineering for higher safety and reliability in dense electronic systems. This guide shows how to upgrade your specifications step by step while staying focused on real world design challenges.

FMVSS 302 vs UL 94 V-0: Why Engineers Are Upgrading

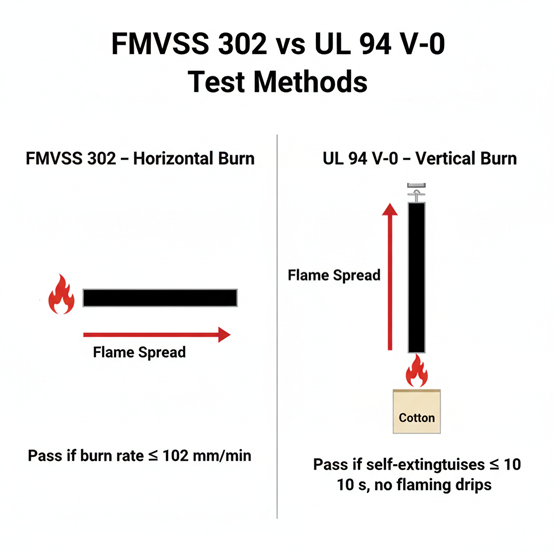

FMVSS 302 was created for automotive interiors to prevent occupant-compartment materials from burning rapidly. The horizontal burn test exposes a specimen to a Bunsen burner for 15 seconds and measures the rate of flame travel. Materials pass if the burn rate stays below 102 mm per minute. The flame may continue along the full sample length, and the material can still pass if it burns slowly.

UL 94 V0 is a vertical burn test used for plastics and foams in electrical and electronic equipment. A vertical specimen is ignited twice for ten seconds each. To earn a V0 rating the material must self-extinguish within 10 seconds and must not drip flaming particles onto the cotton underneath. The test also limits total burning time across five samples to 50 s and prohibits any flaming or glowing that reaches the holding clamp. V0 dictates that materials stop burning on their own, rather than limiting flame spread.

| Standard | Orientation | Ignition | Pass Criteria | Notes |

|---|---|---|---|---|

| FMVSS 302 | Horizontal | 15 s flame Burn rate ≤ 102 mm/min | Flame may spread across full sample if slow. | Common automotive interior test. |

| UL 94 HB/HBF | Horizontal | HB = 30 s flame HBF = 60 s flame |

Slow horizontal burn or self-extinguish | UL’s lowest classification for horizontal testing. Typically harder to pass than FMVSS 302 due to longer exposure time. |

| UL 94 V-0 | Vertical | 2 x 10 s flame | Extinguish ≤ 10 s, no flaming drips, ≤ 50 s total burn time | Highest safety rating; material must self-extinguish quickly with no flaming drips. |

Engineer’s Tip: UL ratings are thickness dependent. Always qualify at or below the thinnest section in your design.

Why the Industry is Shifting

Designers increasingly adopt V-0 because:

- Higher energy density in electronics: Batteries, power converters and control modules have more energy stored in smaller spaces, which increases the risk of fire

- System level testing: System-level standards like UL 9540/9540A evaluate entire BESS or enclosure assemblies. To reduce variables, many engineers “work backwards” by specifying as many UL 94 V-0 components as possible, giving design and reliability engineers greater confidence that the full system test will succeed.

- Customer requirements: Datacenter OEMs often accept only V0 foams for fan tray gaskets and server components. Rail and infrastructure projects align with stringent European standards that are similar to V-0.

- Risk management: While FMVSS 302 remains valid for many automotive trim parts, electronics and battery modules are trending toward V-0 to meet global programs and future regulations.

Step 1 – Map your current specification

- Identify your existing test method.

Are you currently using FMVSS 302 or UL 94 HB/HBF (horizontal orientation)? If your design can be vertical in use, the horizontal method may no longer suffice. - Choose the correct UL 94 class.

- V-0/V-1/V-2: Vertical specimens

- VTM: Thin/flexible materials

- HB/HBF: Horizontal

For electronics gaskets, enclosures, and modules, V-0 is typically the target.

- Define minimum material thickness. UL 94 ratings are thickness dependent. Performance degrades as materials get thinner. Qualify at or below the thinnest section you will use.

- Verify UL listing. Only UL-listed materials have official recognition; always check UL’s database and note the minimum rated thickness and approved colors.

Step 2 – Build a test plan that matches the assembly

- Replicate thickness and construction. When qualifying a foam or gasket, test the actual thickness you plan to use and include adhesive laminates or liners if they will be part of the final assembly. Adhesives can change flame behavior by adding combustible mass; laminated gaskets may require separate testing.

- Use vertical orientation and apply two flame exposures. The V0 test ignites the material twice for 10 seconds each. Ensure the flame is removed until the sample self extinguishes before the second application.

- Check for dripping and afterglow. Place cotton below the sample; the material must not produce flaming drips or ignite the cotton.

- Consider composites. If your gasket is bonded to a bracket or plastic housing, test the composite assembly rather than only the foam. FMVSS 302 also requires composite testing when materials adhere at every point of contact.

Step 3 – Decide where UL 94 V 0 adds value

Not every component needs V0. Use it where ignition risk is highest for:

- Modules, power electronics and battery packs—fire near energy storage can propagate quickly; V0 foams help self extinguish secondary flames.

- Enclosure interfaces and board gap fill—dense assemblies require soft, compressible foam that self extinguishes to protect adjacent circuitry.

- Fan trays, bezels and acoustic seals—V 0 foams combine flame safety with noise and vibration damping, beneficial in data centers.

Where V 0 may not change outcomes:

- Battery cell-to-cell propagation – Controlled by system-level strategies, not gaskets.

- Low-risk exterior trim – FMVSS 302 or UL 94 HB may still suffice.

Step 4 – Choosing UL 94 V-0 materials: Silicone vs. polyurethane Foams

An ideal V-0 foam offers more than flame safety:

- Softness and compressibility for gap filling

- Low stress relaxation to maintain sealing force

- Acoustic damping for noise/vibration control

- Halogen- and siloxane-free chemistry to avoid contamination

Engineer’s Tip: Silicone foams remain the choice for extreme temperatures and outdoor exposure.

Not every design needs the full silicone toolkit. PORON® 40V0 polyurethane foam delivers:

- UL 94 V-0 compliance at 3 mm thickness

- High conformability and softness

- Long-term mechanical stability

PORON 40V0 material is a cost-effective choice for modules, enclosures, NVH pads, and cushioning applications where V-0 flame safety is needed without over specifying.

Step 5 – Validate durability and system performance

Even if a material achieves a UL 94 V-0 rating, long-term reliability depends on how it performs in real-world conditions. Engineers should validate:

- Thermal and mechanical aging – Test the foam under thermal cycling, high humidity, and long-term compression. Properties like compression set (permanent loss of thickness) and stress relaxation (loss of sealing force over time) can degrade in heat or moisture. If sealing force is lost, gaskets can create leak paths, rattles, or enclosure failures.

- Adhesive reliability – Adhesives must maintain bond strength at elevated temperatures and not introduce flame-promoting chemicals. Test peel and shear performance on actual substrates (e.g., coated metals, plastics) and confirm the adhesive does not compromise the foam’s V-0 rating.

- Color and thickness – UL recognition is specific to color and thickness. If your design requires a custom color or thinner gauge, confirm that those are included in the UL listing and qualify across the full range you will use.

Engineer’s Tip: Don’t stop at material data sheets. Assembly-level testing under operating conditions is the best way to ensure your design meets both safety and reliability requirements.

Key Takeaways

- FMVSS 302 allows slow flame spread; UL 94 V-0 requires true self-extinguishing.

- UL 94 ratings depend on thickness, always qualify at your thinnest section.

- Evaluate where V-0 adds value.

- Silicone foams excel in extreme environments; PORON® 40V0 polyurethane foam offers a cost-effective alternative for many electronics and enclosure applications.

- Always validate performance through assembly-level testing, adhesives, and durability checks.

Evaluate PORON® 40V0 material for yourself. Request a free sample to test flame safety, softness, and durability in your application.

Published on Oct 08, 2025