UL 94 V-0 Foams for Data Centers: Managing Noise, Heat, and Fire Risk

As computing power increases, system density rises with it, compressing thermal, mechanical, and safety margins inside server enclosures.

How PORON® 40V0 Foam Improves Low-Frequency Noise and Vibration Control in EVs and Data Centers

We spoke with Eric Beaudry, Technical Service & Development Engineer at Rogers Corporation, to understand how PORON® 40V0 material performs and where it fits best.

The Future of Sealing: How Tomorrow’s Applications Are Changing

In this blog, we look ahead to the future and explore how emerging technologies and evolving markets are reshaping what it takes to seal, protect, and perform.

How to Design Effective Enclosure Vents: Balancing Pressure, Moisture, and Protection

As enclosures get lighter, thinner, and more complex, proper venting has become essential to maintaining performance and protecting sensitive components from pressure, moisture, and contamination.

Where UL 94 V-0 Matters Most: How to Prioritize Flame Ratings in Real-World Designs

As systems become smaller, more powerful, and more integrated, the risk of ignition from electrical or thermal sources continues to rise.

5 Step Guide: Transitioning From FMVSS 302 or UL 94 HB to UL 94 V-0

This guide shows how to upgrade your specifications step by step while staying focused on real world design challenges.

How to Compare O-Rings, Cut Gaskets, Cure-In-Place, and Foam-In-Place Gaskets

Depending on the design priorities, you may need the least expensive seal, the longest lasting seal, one that allows for repeated opening and closing, or one that simplifies manufacturing.

Top 8 Best Practices You Need To Know for Enclosure Die-Cut Gaskets

Die-cut foam gaskets may seem simple, but in enclosure design, they’re anything but. Every design choice can impact the durability and manufacturability of the gasket, as well as how easy it is to install.

From FMVSS 302 to UL 94 V-0: What Engineers Need to Know About Flame Safety Standards

For decades, flammability in automotive design was benchmarked by horizontal burn tests like FMVSS 302. But today, industries are shifting toward the more stringent UL 94 V-0 vertical burn standard.

DeWAL® Materials 101: ePTFE, Conductive Films, & PSA-Backed PTFE/UHMW-PE Explained

In part 2 of this series, we will review how DeWAL® materials are further modified through advanced processes like expansion, conductivity enhancement, and adhesive application to serve even more specialized needs.

Designing with Soft, High-Compressibility V-0 Foams: Gap-Filling in Densely Packed Electronics

As servers, EV modules, and energy storage systems become more compact and powerful, engineers face a recurring challenge: how to manage tight tolerances and protect sensitive components inside densely packed assemblies.

Inside the Launch: Why Rogers Developed PORON® 40V0 Polyurethane Foam

When safety is on the line, engineers often look for materials that meet stringent flame standards such as UL 94 V-0.

How To Validate Enclosure Seal Reliability Through 5 Tests

Through targeted reliability testing, engineers can evaluate how a gasket will perform under specific conditions over time, ensuring it maintains a tight seal and does not fail prematurely.

The Mechanics of Enclosure Seal Design: Gap Spacing, CFD, and Compressibility

Sealing performance is not just about the gasket material you choose, it’s about how that material behaves under compression, over time, and within the mechanical constraints of the enclosure design.

Expert Tips for Preventing Polymer Degradation in Enclosure Applications

What makes a gasket reliable over time? That’s a deceptively complex question. Most materials can seal well right after installation, but what about after 5, 10, or even 15 years in the field?

Sealing the Future of Flight: Precision Solutions for eVTOL Floor Panels

As electric vertical take-off and landing (eVTOL) aircraft reshape the future of advanced air mobility, selecting the right materials for interior components is critical.

Everything You Need to Know About Static vs. Dynamic Seals in Enclosures

In this blog, we explore a foundational concept in gasket engineering: understanding the difference between static and dynamic seals.

UL 94 Flame Ratings: What You Need to Know

When you're designing for electrically sensitive or safety-critical applications, understanding how materials behave under flame exposure is essential.

Solving Mirror Vibration in Heavy-Duty Vehicles with PORON® Polyurethane

CGR Products, a Rogers Preferred Converter, collaborated with Rogers Corporation to deliver a custom vibration-damping solution using PORON® 4701-50 polyurethane.

DeWAL® Materials 101: Understanding PTFE and UHMW-PE for High-Performance Tapes and Films

Making informed design choices requires a clear understanding of a material’s unique properties and what makes it ideal for real-world applications.

What Good Sealing with the Right Partner Looks Like

In this case study, we’ll walk through a real-world example where Marian and Rogers worked together to develop a custom sealing solution after a customer’s original gasket design fell short of performance expectations.

Next-Gen Travel, Next-Level Sealing: Rogers Materials in eVTOL Applications

From cockpit to cargo bay, the next generation of electric vertical takeoff and landing (eVTOL) aircraft is reshaping how we think about mobility.

Introducing the Foam Engineering Lab™: Think you know foam? Think again.

We’re launching the Foam Engineering Lab™—a new educational video series from Rogers Corporation and TBP Converting that breaks down the science of foam selection into clear, practical, and (believe it or not) fun lessons.

Top 8 Sealing Material Options: How to Choose the Right One for Your Enclosure

Seals and gaskets protect enclosures from moisture, dust, chemicals, and temperature extremes. However, not all materials perform equally under different conditions.

Designing for Flight: Silicone Material Solutions for Advanced Air Mobility (AAM)

The future of transportation is taking shape with electric vertical take-off and landing (eVTOL) aircraft. These innovative vehicles bring new challenges in performance, safety, and material reliability.

Top Tips You Need to Know for Silicone Shelf Life, Expiration, Storage, and Handling

Do silicones expire? Can you still use old sheets of foam or solid silicone? And what happens if adhesives are involved?

8 Key Considerations for Designing Reliable Seals and Gaskets

From environmental considerations to material compatibility and long-term durability, here are eight helpful insights into designing seals that stand the test of time.

Enclosure Seal and Gasket Standards Made Easy

Enclosures are essential in industrial, electrical, and electronic applications by protecting critical components from environmental hazards and ensure safe, reliable performance. From shielding sensitive electronics against dust, water, or extreme conditions to preventing costly failures, designing the right enclosure is vital.

Fundamentals of Enclosures: Applications, Sealing, and Protection

At the heart of every reliable enclosure lies one critical component: the seal. Whether protecting sensitive electronics from environmental hazards or enhancing the long-term performance of a system, the seal serves as the first line of defense. Its effectiveness is critical to the functionality and longevity of enclosure systems.

Introducing the Enclosure Institute™: Expert Tools to Design Better Enclosures

Marian Inc. and Rogers Corporation have partnered to bring you the Enclosure Institute™—a free learning platform designed to help engineers navigate the complexities of enclosure sealing.

A Deeper Dive into Temperature Considerations for Silicones, Polyurethanes, PTFE, and UHMW

In our last blog, we outlined why temperature is a crucial factor in design and material selection. Now we will take a closer look into the ideal temperature ranges for specific Rogers Corporation materials.

What You Need to Know About Temperature and Why It's Essential in Elastomeric Material Design

An important design factor for engineers to consider is the temperature at which the material will be exposed throughout the product's life. Elastomeric materials will respond differently to changes in temperature depending on the material chemistry.

Simplify Your Material Search with the New Rogers Material Navigator Tool

Material Navigator Tool is an easy-to-use tool to help you quickly identify elastomeric materials that meet your project requirements.

Stress Relaxation and Why It's Important in Elastomeric Seals

Let's dive into an overview of stress relaxation for elastomeric materials and what you need to know to make informed design decisions.

Foam Firmness vs. Density and Why It's Important

Let's review the fundamentals of density and firmness, how they’re measured, and why both are important in elastomeric material selection.

Top 6 Ways Rogers Technical Service & Development Drives Your Project’s Success

Our Technical Service & Development (TS&D) helps you succeed by offering comprehensive support, expertise, and technical resources for Rogers’ Elastomeric Material Solutions product portfolio.

How to Select a Rail Seat Cushion Material: Top 4 Factors

Explore the four key factors that rail car design engineers should consider when choosing seat cushions for comfort, safety, and long-term durability.

The Ultimate Guide to Compression Force Deflection + Free Tool

When designing for sealing and gasketing applications, two key elastomeric material properties that play a critical role are compression force deflection and compression set.

Top 5 Things You Might Not Know About PTFE Tapes

PTFE (Polytetrafluoroethylene) tapes, also known as high-performance fluoropolymer tapes, are indispensable across industries such as aerospace, automotive, chemical processing, and packaging.

Top 6 Benefits of the Rogers Preferred Converter Network

When you work with a Rogers Corporation Preferred Converter, you are not only choosing a supplier but building a partnership. Learn more about the Rogers Preferred Converter Network.

Winter-Proof Your Train Design with ARLON® Water-Resistant Flexible Heaters

When temperatures plummet and snow covers the ground, trains face unique challenges to keep running smoothly. One of the most critical components affected by harsh winter conditions is the train door.

Everything You Need to Know About Compression Set for Elastomeric Foam Materials

You have probably seen compression set values, or C-set, on a Technical Data Sheet for an elastomeric material before, but have you ever wondered what exactly those values mean.

Protecting Athletes Step by Step During the Paris Olympics

In intense competitions including track and field, soccer, handball, tennis, rugby, and more, footwear is a crucial extension of an athlete’s ability to compete at the highest level.

The Engineer's Toolkit: 8 Best Tools for Effective Material Selection

Time is valuable when it comes to product design. Having the right tools to make informed decisions can be the key distinction between a successful project and one that doesn't meet expectations.

How to Choose a Reputable Silicone Supplier: Top 6 Tips

Whether you're buying a silicone foam, solid, or sponge, you want to make sure you are buying from a reputable manufacturer. The quality of the material you source can significantly impact the integrity and reputation of your product.

Let's Compare: Silicone vs Polyurethane vs EPDM and More

Are you considering silicone and want to know how it compares to other commonly used elastomers? Maybe you’re just wondering if there are any good alternatives to silicone? You’ve landed in the right place.

Top 7 Unique Silicone Advantages You Can't Ignore

When you think of silicones, your first thought may be gaskets and seals, but silicones are also used in addressing all sorts of gap-filling, shock, and vibration challenges across thousands of mission-critical applications and industries.

How to Narrow Down Silicone Brands from Rogers Corporation

Rogers offers three brands of silicones: BISCO® silicones, ARLON® silicones, and Silicone Engineering® materials. Each brand has a distinctive focus that caters to the differing needs of engineers.

The Key Differences You Need to Know About Silicone Types

Silicone is a superhero in the world of materials! Not only does it offer stellar performance in a wide range of applications, but it is also versatile, coming in many different forms tailored to meet specific needs.

Beyond the Price Tag: Long-Term Savings with Silicone

We know budget is important when designing products, so it is worth considering: could selecting silicone actually save you money in the long run? Read on to learn about the top six long-term benefits of silicone.

Back to Silicone Basics: An Overview of Cellular Silicones and Solids

Design engineers have many details to consider when choosing the right materials for advanced applications. Learn more about what makes silicone a material of choice from Rogers’ Principal Technical Service and Development Engineer Dan Kubick.

Silicone Application and Industry Overview

People are often surprised to learn about the many different applications and industries that rely on the superior performance of silicone materials. From the aerospace and defense sector to healthcare and renewable energy, silicones have quietly become a mission-critical material across a wide range of fields.

How to Choose the Right Silicone: Top 6 Considerations

Whether you're working on a sealing gasket, electronic component, or a different application, choosing the right silicone material is paramount.

New DeWAL® Tool Improves Search and Offers Advanced Features

The DeWAL® Product Properties Guide is a new addition to Rogers’ library of tools that has streamlined customers’ approach to searching, filtering and sorting product specifications.

Supporting USA Luge with New Applications for BISCO® Silicones

Rogers Corporation was proud to support USA Luge in the Beijing Games. Discover how the partnership first started and why athletes now rely on the BISCO® Silicone pads in their sleds.

5 Perks of a Virtual Trade Show

As our industry adapts to the evolving tradeshow landscape, many events have transitioned their “brick-and-mortar” presence to virtual trade show experiences as a way to connect industry participants in a socially distant world. Virtual shows and events are a viable and cost-effective option to generate additional engagement when traditional shows are not practical.

Sourcing a Sustainable Materials Partner: Four Factors to Consider

Consumer behaviors are shifting when it comes to making purchasing decisions. While price point or design used to be the primary factors influencing a person’s decision to buy footwear, increasingly we are seeing more emphasis on durability and environmental impact—particularly among younger consumers.

Meeting the Footwear Comfort and Protection Needs of Today’s Healthcare Workforce

Today’s health care workers are having more demands placed on them than ever before. Longer shifts, more days at work and more activity overall are taking a toll on their bodies. Having proper footwear is a critical factor in their comfort -helping to provide support, reduce back strain, alleviate pain and provide an added layer of protection.

Defining the Future of Footwear at Rogers Corporation

Technology is moving at a rapid pace and consumers are constantly in search of the latest in innovation. This is true for the latest electronics and, yes, even shoes. When it comes to footwear, comfort, style, and functionality remain important, but people are also looking for the latest features that technology can offer.

PORON® Vive Helping to Create the Future of Footwear

From hiking boots to running shoes to dress pumps, innovation in footwear is moving at a rapid pace. Designing for the footwear market requires constant innovation and a continuous search for the best materials.

Footwear Performance Materials, Italian Style, Part 3

Would you be surprised to learn that high-tech and high-fashion are often closely linked? One unique company, Italian-based Omnipel Technologies, makes it their mission to address global footwear trends with high performance material solutions.

Footwear Performance Materials, Italian Style, Part 2

Would you be surprised to learn that high-tech and high-fashion are often closely linked? One unique company, Italian-based Omnipel Technologies, makes it their mission to address global footwear trends with high performance material solutions.

Footwear Performance Materials, Italian Style, Part 1

Would you be surprised to learn that high-tech and high-fashion are often closely linked? One unique company, Italian-based Omnipel Technologies, makes it their mission to address global footwear trends with high performance material solutions.

Designed for Marathons: New ARES Running Shoes with PORON® Performance Comfort Technology

In recent years, marathons have been held in major cities to build up our bodies, challenge ourselves, and promote the city image. A marathon is not only a traditional sports event, but also a healthy fashion trend.

Enabling Safety Applications with Rogers’ Products

At Rogers Corporation a large part of our culture is our dedication to safety, in both the workplace and our environment. Many of our products enable safety-related applications, embodying the “protect” aspect of our commitment to help power, protect and connect our world.

How Rogers’ XRD® Material Helped Create an Innovative Training Shoe

When Fabrizio Belli, a businessman, and Francesco Cozzo, a researcher, met more than 17 years ago, they didn’t know that one day they would develop and produce a very unique product – the GRIN shoe. Years later, their highly scientific innovation process led to the creation of the GRIN training shoes, designed to reduce fatigue, enhance toning, and improve posture.

Designing for Thermal Management

In our first blog in this series, we explored thermal conductivity and its measurement techniques and explained why your thermal interface material may not be as conductive as you think if you are relying on vendor data sheets. In this blog, we’ll take a closer look at two other measures used in evaluating thermal interface materials (TIM).

My Marathon Training Surprise: PORON® Vive® Insoles

I’ve always liked to run, but typically I was in that 2-4 miles per run realm. A few months ago, I got involved with St. Jude Children’s Research Hospital and decided to run a half marathon and raise some money for the kids at St. Jude.

Why Your Thermal Interface Material May Not Be as Conductive as You Think: Exploring Thermal Conductivity & Measurement Techniques

If you’re an electronics designer or assembler addressing thermal management issues, safety is likely your number one concern. When selecting a thermal interface material (TIM) to dissipate heat, you probably started by comparing the thermal conductivity (K) of your options. But did you know that manufacturers’ advertised values of thermal conductivity can be widely inaccurate?

Buying Shoes That Sell: A Sneak Peek Into the World of Retail Shoe Buying, Part 3

A member of our Rogers’ marketing communications team had the opportunity to work for a brief stint on the shoe buying team of one of America’s largest retailers. As Rogers is a major supplier of cushioning materials to the shoe industry, we thought it would be fun to learn more about her experience from the “other side of the desk.”

Buying Shoes That Sell: A Sneak Peek Into the World of Retail Shoe Buying, Part 2

A member of our Rogers’ marketing communications team had the opportunity to work for a brief stint on the shoe buying team of one of America’s largest retailers. As Rogers is a major supplier of cushioning materials to the shoe industry, we thought it would be fun to learn more about her experience from the “other side of the desk.”

Buying Shoes That Sell: A Sneak Peek into the World of Retail Shoe Buying, Part 1

A member of our Rogers’ marketing communications team had the opportunity to work for a brief stint on the shoe buying team of one of America’s largest retailers. As Rogers is a major supplier of cushioning materials to the shoe industry, we thought it would be fun to learn more about her experience from the “other side of the desk.”

Foam Properties: What Makes One Foam Different From Another?

In a word (or three), not so much. Our customers are often surprised to learn that all PORON® Comfort materials are open cell polyurethane foams, especially when what they’re used to seeing are closed cell EVA foams or closed cell polyurethane foams.

Meet the Seats: Rogers’ BISCO® Silicone Material Makes Commuting Comfortable

Seating is an inarguably critical feature for many commuters, whether they’re traveling in planes, cars, buses, or trains. An uncomfortable seat can turn the easiest of commutes into a long, uncomfortable trek.

Rogers Takes the Ice at PyeongChang

Chances are you’ve tuned into the 2018 Olympic Winter Games over the course of the last few days. You may be surprised to learn that, in addition to the athletes, cheering fans, and news crews, Rogers Corporation has a presence at the Games.

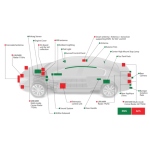

EVs, HEVs Push for Development of More Advanced Battery Management Systems & Power Semiconductors

Twelve countries around the globe have set goals to end the sale of gas- and diesel-powered vehicles starting in 2040. This will significantly accelerate the uptake of electric vehicles (EVs) and hybrid vehicles (HEVs). It will also increase the need for improved battery management systems to monitor and control the high-voltage battery stacks, and for power semiconductor devices for battery management, on-board charging, infotainment, electric motors, and more.

Designing High Performance Sealing Gaskets for Automotive Brake Lights

A Chinese automobile manufacturer identified an issue with water leaking into the brake light of one of its models, causing short circuits and potentially a fire. The deterioration of the EPDM material originally used to seal around the brake light caused the leakage.

Impact Protection: How to Protect Baseball Players From Impacts of 100+ mph

Unlike the baseball or baseball bat, the baseball glove was initially not part of the game. Back when most of the throwing was underhand, players used their hands. Fast forward to today and it’s a very different ball game. The Guinness World Record for the fastest baseball pitch is 105.1 mph, thrown by Aroldis Chapman for the Cincinnati Reds vs the San Diego Padres on September 24, 2010. Enter the need for impact protection.

Rogers Corp. Broadens AquaPro® 37™ Polyurethane Materials for Sealing

Rogers Corporation announces an extension of the thickness range for AquaPro® 37™ – the material of choice for long-lasting protection of sensitive electronics and enclosed devices.

eMobility: Overcoming the Challenges of Vibration Management, Gasketing, and Sealing in EVs / HEVs

Recent developments in eMobility (electro mobility or advanced mobility) have led to increasing options for clean and efficient vehicles that rely on electric powertrain technologies, in-vehicle information, communication technologies, and connected infrastructures. The systems within these vehicles pose unique sealing and vibration management challenges vs cars with traditional combustion engines.